Temperature-Sensitive Trigger Thermal Fuse Ensures Rapid Protection Against Overheating Risks

News 2025-11-27

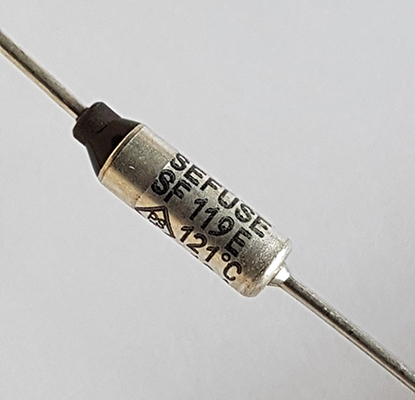

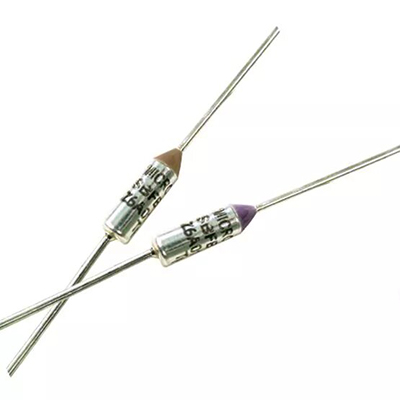

Temperature-sensitive trigger thermal fuses are key safety components in modern electronic and electrical systems, designed to interrupt current when abnormal heat is detected. Unlike resettable protectors, a thermal fuse performs a one-time, irreversible cutoff that prevents damage to circuits, batteries, and surrounding materials. By integrating precise temperature calibration and stable materials, these devices provide dependable protection in compact, cost-sensitive designs commonly found in consumer electronics, industrial control units, and power conversion equipment.

Operating Principle and Design Characteristics

A temperature-sensitive trigger thermal fuse consists of a thermal pellet or alloy element calibrated to melt or deform at a defined temperature, a spring or contact mechanism, and a sealed housing. Under normal operating conditions, the internal element maintains firm electrical contact, allowing current to flow with minimal resistance. Once the ambient or component temperature exceeds the rated threshold, the thermal element rapidly changes state, releasing the spring and mechanically separating the contacts. This fast mechanical action is the core advantage: activation occurs within a narrow temperature band, limiting exposure to hazardous overheating and preventing cascading failures in densely populated PCBs.

Key Performance Advantages and Safety Benefits

Performance is defined primarily by trip temperature, holding temperature, current-carrying capacity, and insulation resistance. A well-designed thermal fuse offers precise calibration, low contact resistance before activation, and high dielectric strength after opening. Rapid response to heat reduces the risk of smoke, fire, or catastrophic component breakdown, even under fault conditions such as stalled motors, blocked air vents, or charger short circuits. The compact construction enables direct placement close to heat sources, ensuring accurate sensing of local temperature rather than relying solely on ambient measurements. Once activated, the permanent open circuit prevents automatic restart, forcing a targeted service action that supports safety compliance and product liability requirements.

Application Scenarios Across Industries

Temperature-sensitive trigger thermal fuses are widely integrated in AC adapters, battery packs, LED drivers, coffee makers, hair dryers, and other household appliances where overheating is a common risk. In industrial environments, they protect transformers, SMPS modules, servo drives, and heating elements in process equipment. The fuse is typically installed in series with the primary power path, close to coils, windings, or high-loss components. In lithium-ion battery packs, it often works alongside PTC devices and electronic protection ICs, adding a purely thermal, non-software-based safety layer. Automotive electronics adopt these fuses in seat heaters, blower motors, and on-board chargers to meet stringent functional safety and thermal management standards.

Selection Considerations and Integration Practices

Correct selection of a thermal fuse requires aligning rated operating temperature and current with the real thermal profile of the application. Engineers must evaluate maximum ambient conditions, expected heat rise, and fault scenarios to define a suitable cutoff temperature that protects components while avoiding nuisance trips. Mechanical mounting and thermal coupling are equally important: tight contact to the heat source, use of thermally conductive sleeving, and secure lead fixing improve response time and repeatability. When used together with thermostats, PTC thermistors, or electronic overcurrent protection, the fuse acts as a final safeguard layer, helping manufacturers comply with UL, IEC, and EN safety standards and supporting clear safety messaging in product datasheets and marketing materials.

Typical Questions About Temperature-Sensitive Trigger Thermal Fuses

1What happens after a thermal fuse activates?

The fuse opens the circuit permanently; it cannot be reset and must be replaced to restore operation.

2How is the correct cutoff temperature selected?

Engineers choose a rated temperature based on normal operating range, worst-case heat rise, and safety margins defined by relevant standards.

3Can a thermal fuse replace electronic overcurrent protection?

It is not a substitute for electronic protection but a complementary safeguard, providing independent thermal shutdown if other systems fail.