Terminal Corrosion Signs In Fuse Box That Require Immediate Attention In Modern Systems

News 2025-12-22

Corroded terminals in a fuse box are a frequent root cause of intermittent faults, overheating, and unexpected system shutdowns in automotive, industrial, and power distribution applications. Moisture ingress, chemical exposure, and temperature cycling gradually attack metal surfaces, creating high resistance joints that compromise current flow and protection accuracy. Recognizing early warning signs and acting quickly protects sensitive loads, stabilizes system performance, and prevents costly downtime or safety incidents.

Visual Indicators Of Terminal Degradation

Corrosion usually appears as white, green, or dark brown deposits around fuse clips, screw terminals, and bus bars. Flaking metal, pitting, and discoloration near the contact area signal that conductive surfaces are being reduced, which raises contact resistance. Warped plastic housings, burn marks, or melted insulation indicate localized heating caused by poor connections. In sealed automotive fuse boxes, foggy covers or water traces around gaskets are strong evidence of moisture entry that accelerates terminal degradation.

Electrical Symptoms Affecting System Performance

Beyond visible damage, corrosion generates functional issues such as voltage drops under load, nuisance fuse blowing, dim or flickering lights, delayed relay activation, and unstable control electronics. In precision electronic assemblies, small resistance increases at corroded terminals can distort sensor readings or timing signals, degrading overall control accuracy. These symptoms often disappear temporarily when the harness is moved, misleading technicians unless terminal integrity and contact pressure are inspected under real operating conditions.

Application Scenarios And Performance Advantages Of Proper Maintenance

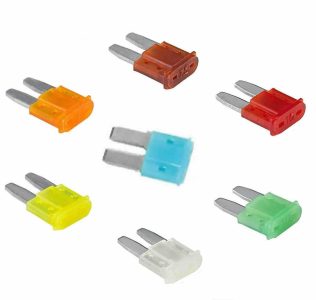

Automotive power distribution units, photovoltaic combiner boxes, industrial control cabinets, and marine electrical panels all operate in harsh environments where terminal corrosion risk is high. Implementing routine inspection, cleaning using appropriate contact cleaners, and replacement of damaged terminals restores low-resistance paths and preserves fuse response characteristics. Using plated copper alloys, sealed fuse holders, and correctly rated terminal blocks offers superior conductivity, extended life, and better heat dissipation, which stabilizes performance in high-current and mission-critical applications.

Preventive Measures And Component Selection Strategies

Designers and maintenance teams should prioritize IP-rated enclosures, venting strategies that limit condensation, and cable glands that prevent water wicking. Selecting terminals and fuse holders with corrosion-resistant plating, secure locking mechanisms, and adequate contact force reduces micro-arcing and oxidation. Applying approved dielectric greases in moisture-prone sites helps block contaminants without impairing conductivity at the mating surfaces. These practices sustain low contact resistance, improve fault-clearing reliability, and support long-term operational efficiency in demanding electrical environments.

1. What are early signs of terminal corrosion in a fuse box?

Discoloration, powdery deposits, loose terminals, and minor heat marks around fuses are common early indicators.

2. Why does corrosion affect fuse performance?

Corrosion increases contact resistance, causing local heating, voltage drops, and delayed or inconsistent fuse operation.

3. How often should fuse box terminals be inspected?

In harsh or high-vibration environments, inspection at least every 6–12 months helps maintain stable, safe performance.