Truck Battery Box with Terminal Protection Covers to Avoid Short Circuits

News 2025-10-31

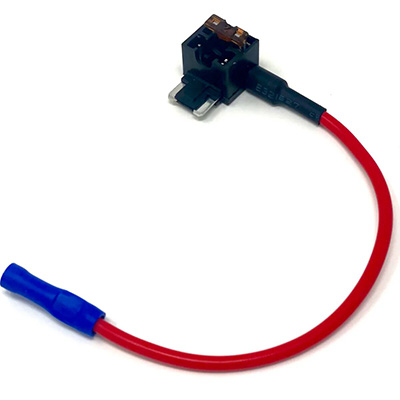

In the realm of automotive and heavy machinery, ensuring electrical safety is paramount. The truck battery box equipped with terminal protection covers serves as a critical component in preventing short circuits, which can lead to fires, equipment damage, or even catastrophic failures. These covers are engineered to insulate battery terminals, safeguarding against accidental contact with metal objects or conductive materials. By integrating such features, manufacturers address common risks in environments where vibrations, moisture, and rough handling are prevalent, making this solution essential for reliable operation in various industrial and commercial settings.

Applications in Heavy-Duty Environments

Truck battery boxes with terminal protection are widely used in construction sites, mining operations, and long-haul transportation. In these scenarios, vehicles endure extreme conditions, including dust, water exposure, and mechanical stress, which heighten the risk of short circuits. For instance, in mining trucks, where heavy loads and rough terrain are standard, these covers protect against debris-induced faults. Similarly, in emergency vehicles like fire trucks, the protection ensures that battery systems remain operational and safe, even during rapid maneuvers or exposure to harsh weather, thereby enhancing overall vehicle reliability and longevity.

Performance and Safety Enhancements

The design of terminal protection covers significantly boosts battery system performance by reducing the likelihood of electrical failures. Made from durable, insulating materials like high-grade plastics or rubber, these covers offer resistance to corrosion and impact, ensuring long-term protection. Key advantages include improved energy efficiency through minimized parasitic drains and enhanced safety by complying with industry standards such as ISO 16750. In practical terms, this means fewer downtime incidents and lower maintenance costs for fleet operators, as the covers effectively shield terminals from environmental factors, promoting consistent power delivery and system integrity.

Frequently Asked Questions

1. What materials are used for the terminal protection covers?

They are typically made from non-conductive, durable plastics or rubber compounds that resist heat, moisture, and chemicals.

2. How do these covers improve battery lifespan?

By preventing short circuits and corrosion, they reduce wear on battery terminals, extending overall battery life and reducing replacement frequency.

3. Can these protection covers be retrofitted to existing battery boxes?

Yes, most designs are compatible with standard truck battery setups, allowing for easy installation without major modifications.