Trunk Light Fuse Safeguards Vehicle Cargo Area Lighting Circuits Effectively

News 2025-11-17

The trunk light fuse plays a small but decisive role in modern vehicle electrical systems. Positioned in the fuse box and dedicated to the trunk or cargo area lamp circuit, this component prevents damage caused by short circuits, moisture intrusion, pinched wiring, or overloaded accessories. By disconnecting power when current exceeds a defined threshold, the fuse protects wiring harnesses, connectors, and sensitive body control modules. For automotive designers, distributors, and maintenance professionals, understanding the behavior and specifications of the trunk light fuse is vital to sustaining dependable cargo illumination and avoiding costly harness repairs.

Function and Operating Principle of the Trunk Light Fuse

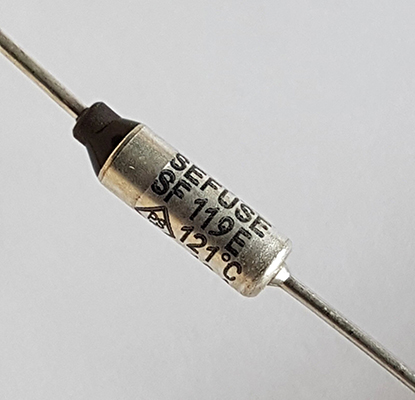

The trunk light fuse is typically a blade‑type automotive fuse matched to the current demand of the cargo area lamp, usually in the 5–15 A range. Its element is engineered to melt when abnormal current flows, interrupting the circuit in milliseconds and preventing thermal damage. This fuse is calibrated not only for steady‑state current but also for inrush demands of LED drivers or incandescent bulbs at switch‑on. Integration into the main body electronics architecture ensures that trunk illumination remains on a dedicated, clearly labeled circuit, which simplifies diagnostics and fuse replacement during service. Proper rating selection prevents nuisance blows while maintaining robust overcurrent protection.

Key Performance Advantages in Automotive Applications

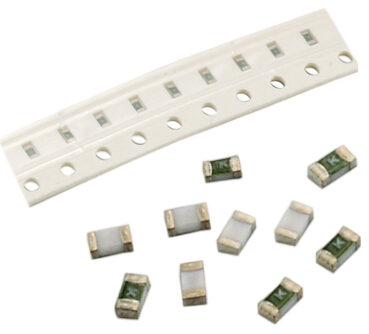

High‑quality trunk light fuses deliver low resistance, stable temperature characteristics, and predictable time‑current curves across wide ambient conditions. In passenger cars, SUVs, and commercial vans, cargo areas are exposed to vibration, dust, humidity, and temperature swings, all of which increase the likelihood of wiring faults. The fuse safeguards wiring looms routed near hinges, liftgates, and folding seat structures. Compatibility with both conventional bulbs and low‑power LED modules enables vehicle platforms to upgrade lighting technology without redesigning basic protection. Standardized footprints and color coding support fast assembly in OEM production lines and minimize errors during aftermarket service.

Application Scenarios in Trunks, Cargo Bays, and Utility Fleets

Trunk light fuses see widespread deployment in sedans, hatchbacks, delivery vans, station wagons, and light trucks where cargo visibility is essential for safety and logistics. In fleet vehicles, frequent loading cycles increase wear on harnesses and switches; a correctly specified fuse becomes the primary defense against localized overheating and insulation failure when doors slam or cargo shifts against panels. Specialty vehicles that integrate auxiliary power sockets, aftermarket amplifiers, or refrigerated compartments near the cargo area benefit from dedicated fused branches that isolate the lighting from other loads. This segmentation allows technicians to troubleshoot dim or inoperative trunk lamps without disturbing mission‑critical systems.

Selection, Maintenance, and Typical Troubleshooting Practices

When selecting a trunk light fuse, engineers evaluate nominal voltage, current rating, blow characteristics, and compliance with automotive standards such as ISO and SAE specifications. During maintenance, repeated fuse failures indicate underlying problems such as frayed insulation at the trunk hinge, corroded lamp holders, or incorrect bulb wattage. Technicians should always replace a blown fuse with the same rating and type, never a higher value that could mask a fault and risk harness damage. Periodic inspection of the cargo area lamp wiring and fuse box labeling supports safer vehicle operation, reduces downtime, and preserves electrical system integrity across the vehicle’s lifetime.

1. Why does the trunk light fuse blow repeatedly?

A recurring blown trunk light fuse usually points to a shorted wire near the trunk hinge, moisture inside the lamp assembly, or the installation of a higher‑wattage bulb or accessory than the circuit was designed to support.

2. Can LED trunk lights use the same fuse rating as halogen bulbs?

Often yes, but only if the total current draw remains within the original design margin; many LED kits reduce current, yet poor‑quality drivers may create spikes that still require verification of fuse size and time‑current compatibility.

3. Where is the trunk light fuse typically located in a vehicle?

In most vehicles the trunk light fuse resides in the interior or under‑hood fuse box, clearly marked on the cover diagram, and typically grouped in the body electronics or interior lighting section of the panel.