Vibration-Resistant Thermal Fuse Ensures Stable Protection In Dynamic Vehicle Environments

News 2025-11-27

Vibration-resistant thermal fuses are increasingly vital in modern vehicles, where compact layouts and high power densities generate intense heat and constant motion. Unlike standard fuses that may loosen or fatigue under persistent vibration, these components are engineered to remain mechanically stable while maintaining precise thermal cutoff characteristics. They act as passive, fail-safe protectors against overheating, preventing damage to wiring, motors, battery modules, and control electronics in demanding automotive conditions.

Key Applications In High-Motion Vehicle Zones

Vibration-resistant thermal fuses are used in electric power steering, oil and water pumps, engine cooling fans, ABS modules, and seat adjustment motors, all of which experience continuous vibration and temperature cycling. In hybrid and battery electric vehicles, they safeguard battery packs, DC/DC converters, inverters, and on-board chargers, where both mechanical shock and thermal stress are present. They are also placed in HVAC blower systems and PTC heaters to stop overheating in confined ducts. By integrating these fuses directly into harnesses or motor windings, manufacturers achieve localized, fast thermal response that matches the real heat profile of each subsystem.

Performance Advantages Under Vibration And Thermal Stress

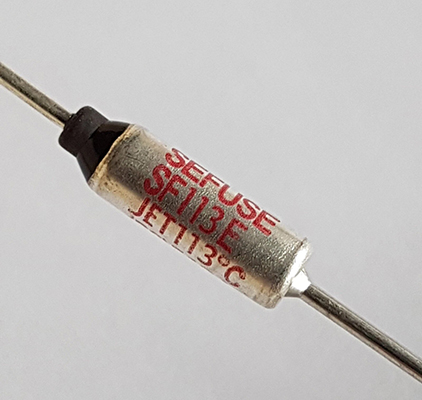

These fuses incorporate reinforced terminals, secure crimp or weld interfaces, and rigid internal structures that prevent contact chatter or micro-movement under vibration. The thermal pellet or organic trigger element is calibrated to a narrow cutoff tolerance, ensuring accurate opening temperatures even after long-term exposure to engine bay conditions. Low internal resistance reduces self-heating, supporting stable operation at rated current. Many series are tested according to automotive vibration profiles and thermal shock cycles, demonstrating consistent trip behavior and mechanical integrity across the product lifetime.

Design And Integration Considerations For OEMs

When selecting a vibration-resistant thermal fuse, engineers must align opening temperature, current rating, and interrupting capacity with the specific load and ambient conditions of the vehicle zone. Mounting method is equally important: radial, axial, and surface-mount styles each suit different packaging strategies and vibration directions. Proper strain relief in leads and correct orientation relative to heat sources improve detection accuracy and durability. Compliance with AEC-Q standards and adherence to PPAP documentation requirements helps OEMs streamline qualification. Collaborative testing, including worst-case vibration and overload scenarios, confirms that the fuse opens predictably before neighboring plastics, insulation, or semiconductor devices reach critical temperatures.

Safety, Compliance, And Lifecycle Benefits

By preventing thermal runaway in tightly packed modules, vibration-resistant thermal fuses support functional safety goals and help manufacturers align with ISO 26262 concepts at the hardware level. They act as a final protective layer when active control or software fails, reducing the risk of fire, smoke, or irreversible damage to expensive battery and power electronics assemblies. Stable performance over the vehicle lifetime reduces warranty claims and maintenance costs, while compact form factors free space for additional functionality. Their passive, no-power design fits well into energy-efficient architectures and simplifies compliance with global automotive and electrical safety standards.

1、Where are vibration-resistant thermal fuses most commonly installed in vehicles?

They are frequently installed in battery packs, power steering units, cooling fans, pumps, ABS modules, HVAC blowers, and seat or window motors that experience both heat and vibration.

2、How do these fuses differ from standard thermal fuses?

They use reinforced mechanical structures, vibration-tested terminations, and calibrated thermal elements that maintain precise opening temperatures under continuous mechanical shock and temperature cycling.

3、What should designers evaluate when choosing such a fuse?

Designers should evaluate opening temperature, current rating, interrupting capacity, mounting style, vibration profile, ambient conditions, and compliance with automotive standards such as AEC-Q and relevant safety regulations.