Wire Harness Material Selection Based on Automotive Safety Standards and Environmental Requirements

News 2025-10-24

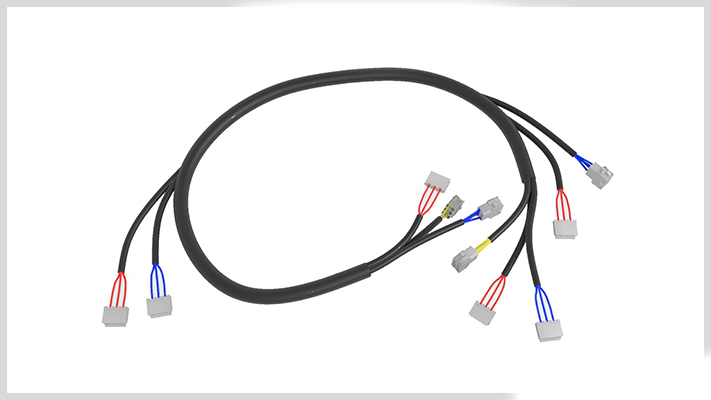

Wire harnesses are essential in automotive systems, acting as conduits for electrical signals between components like sensors and control units. Proper material selection ensures reliability under extreme conditions, adhering to safety standards that prevent failures and environmental regulations that reduce ecological harm. This approach enhances vehicle longevity and performance in real-world applications, such as high-speed driving or exposure to varying climates.

Automotive Safety Standards for Material Choice

Materials for wire harnesses must comply with standards like ISO 26262 and FMVSS to mitigate risks in safety-critical scenarios. For example, insulation materials need high flame retardancy and resistance to abrasion, using options like cross-linked polyethylene for better thermal stability. This selection improves durability, reducing the chance of short circuits in engine bays or during collisions, thereby supporting safer automotive designs.

Environmental Regulations Guiding Material Decisions

Environmental mandates, including RoHS and REACH, restrict hazardous substances in wire harness components, favoring sustainable alternatives. Conductors and insulators are chosen for recyclability and low toxicity, such as halogen-free polymers that maintain electrical integrity while minimizing environmental impact. In electric vehicles, these materials aid energy efficiency and ease of disposal, aligning with global efforts to lower carbon footprints without compromising functionality.

Application Scenarios and Performance Benefits

In diverse automotive contexts, material choices optimize wire harness performance. For instance, in autonomous systems, high-conductivity copper with robust insulation ensures precise signal transmission under vibration, enhancing accuracy and response times. Benefits include weight reduction for better fuel economy and resistance to corrosion in harsh environments, making harnesses more reliable and cost-effective over the vehicle’s lifecycle.

Frequently Asked Questions

1. What key factors drive wire harness material selection?

Answer: Factors include adherence to safety standards for durability and environmental rules for sustainability, ensuring optimal performance in automotive applications.

2. How do safety standards impact material reliability?

Answer: They require materials to withstand extreme conditions, like heat and stress, minimizing failure risks and enhancing overall vehicle safety.

3. What advantages come from environmentally compliant materials?

Answer: They reduce hazardous waste, support recycling, and maintain high electrical performance, facilitating compliance with international regulations.