Ceramic Fuse: Specifications, Industry Uses & Selection Guide

Introduction

A ceramic fuse is a critical overcurrent protection component widely used in electronic and electrical systems, designed to safeguard circuits and equipment from damage caused by excessive current. Unlike glass fuses, ceramic fuses feature a ceramic body that offers superior thermal resistance, high breaking capacity, and enhanced safety—making them ideal for high-voltage, high-current, and harsh-environment applications. As a key element in ensuring operational reliability, ceramic fuses are integrated into countless devices and systems across diverse industries, with their performance and specifications tailored to meet specific usage requirements.

Key Applications of Ceramic Fuses in Daily and Industrial Scenarios

Ceramic fuses find extensive use in scenarios where stability and safety under extreme conditions are non-negotiable. In household electronics, they are commonly installed in power supplies of televisions, refrigerators, and washing machines to prevent circuit burnout due to voltage fluctuations. In automotive systems, they protect critical components like the engine control unit (ECU), lighting circuits, and battery management systems from short circuits. Industrial applications further expand their scope, including use in power distribution cabinets, motor drives, and renewable energy systems (such as solar inverters and wind turbine controllers), where they withstand high temperatures and heavy current loads to ensure continuous operation.

Major Industries Relying on Ceramic Fuses for Protection

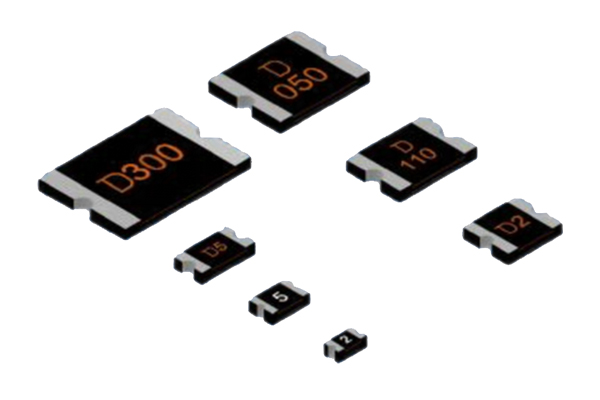

The versatility of ceramic fuses makes them indispensable across multiple industries, each leveraging their unique properties to address sector-specific challenges. The electronics manufacturing industry uses ceramic fuses in smartphones, laptops, and industrial control boards, as their compact size and high insulation resistance fit miniaturized circuit designs. The automotive industry, especially with the rise of electric vehicles (EVs), depends on high-voltage ceramic fuses (e.g., 400V-800V) to protect battery packs and powertrain systems. The energy sector, including power plants and grid infrastructure, utilizes ceramic fuses in transformers and switchgear to prevent catastrophic failures. Additionally, the medical equipment industry integrates ceramic fuses into devices like MRI machines and patient monitors, where reliable overcurrent protection is vital for patient safety.

Ceramic Fuse Product Models, Specifications and Parameters

The following table outlines common ceramic fuse models, their specifications, and key parameters to help users select the appropriate product for their applications:

| Model Number | Rated Voltage (V) | Rated Current (A) | Breaking Capacity (A) | Operating Temperature Range (°C) | Body Diameter (mm) | Body Length (mm) |

| CF-1000 | 250 | 0.5 – 20 | 100 | -40 to +125 | 5 | 20 |

| CF-2000 | 500 | 1 – 30 | 200 | -40 to +150 | 6.3 | 30 |

| CF-3000 | 600 | 2 – 40 | 300 | -40 to +180 | 8 | 45 |

| CF-4000 | 1000 | 5 – 60 | 500 | -40 to +200 | 10 | 60 |

| CF-5000 | 1250 | 10 – 80 | 800 | -40 to +220 | 12.7 | 75 |

Each model is engineered to meet international standards (e.g., IEC 60127, UL 248) and undergoes rigorous testing to ensure consistent performance. The rated current and voltage indicate the maximum safe operating limits, while the breaking capacity represents the highest current the fuse can interrupt without exploding or causing damage. The operating temperature range ensures suitability for both indoor and outdoor environments, from cold industrial warehouses to high-temperature engine bays.

Advantages of Ceramic Fuses Over Other Fuse Types

Ceramic fuses offer distinct advantages that make them a preferred choice in many applications. Their ceramic body provides excellent thermal conductivity and arc-quenching capabilities, allowing them to handle higher currents and voltages compared to glass fuses. Unlike glass fuses, which may shatter when overloaded, ceramic fuses maintain structural integrity, reducing the risk of debris contaminating nearby components. Additionally, ceramic fuses have a lower resistance and faster response time, ensuring rapid circuit protection when an overcurrent event occurs. Their resistance to corrosion and chemical damage also extends their lifespan in harsh environments, making them more cost-effective in the long run for industrial and automotive applications. These benefits, combined with their wide range of specifications, make ceramic fuses a reliable solution for overcurrent protection across industries.