Advanced Wire Harness Designs for Automotive Seat Adjustment and Heating Electricals

News 2025-10-31

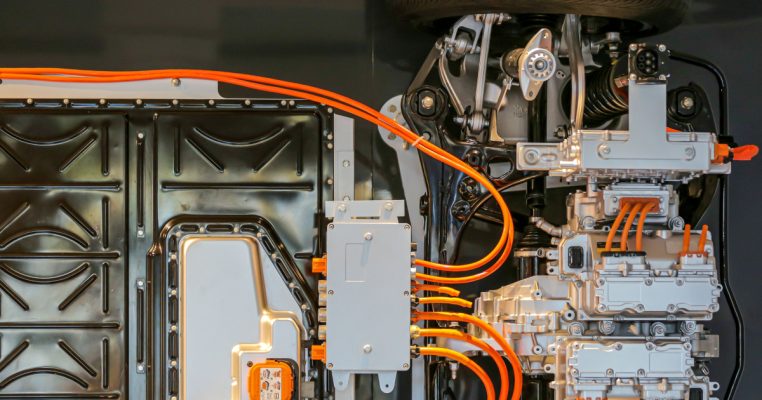

Wire harnesses are critical components in modern automotive systems, particularly for features like seat adjustment and heating that enhance driver and passenger comfort. In automotive engineering, these harnesses integrate multiple electrical connections to manage complex functionalities such as motorized seat movements and temperature controls. Advanced designs focus on optimizing connectivity, reducing weight, and improving reliability to meet the demands of electric and hybrid vehicles. By incorporating high-quality materials and precise engineering, these wire harnesses ensure seamless operation, minimize electrical failures, and support the integration of smart technologies for better user experiences in various vehicle types.

Application Scenarios

In luxury sedans and SUVs, wire harnesses for seat adjustment handle precise motor controls for features like lumbar support and reclining positions, ensuring smooth and responsive adjustments. For heating electricals, they connect heating elements in seats and steering wheels, providing rapid warm-up in cold climates while integrating with climate control systems. These designs are also vital in electric vehicles, where they manage energy-efficient connections that reduce power loss and support regenerative braking systems. Additionally, in commercial fleets, robust harnesses withstand harsh conditions, offering reliable performance for long-haul drives and frequent seat usage.

Performance Advantages

Advanced wire harness designs offer superior durability through the use of corrosion-resistant materials and shielded cables, which protect against electromagnetic interference and extend component lifespan. They achieve weight reduction by employing compact, high-density connectors, improving fuel efficiency and vehicle handling in both internal combustion and electric models. Enhanced thermal management ensures consistent performance in heating systems, with faster response times and even heat distribution, reducing energy consumption. Moreover, these harnesses facilitate easier installation and maintenance, lowering manufacturing costs and downtime for automotive manufacturers and service technicians.

1. What are the main benefits of advanced wire harnesses in automotive applications?

They provide better reliability, reduced weight, and improved energy efficiency, enhancing overall vehicle performance and longevity.

2. How do wire harnesses integrate with seat heating systems?

They connect heating elements to power sources and control units, ensuring safe and efficient operation with minimal heat loss.

3. Why are customized designs important for different vehicle types?

Custom designs accommodate specific electrical requirements, space constraints, and environmental factors, optimizing functionality for various automotive models.