Automotive Battery Box Durable Plastic Ensures Long-Lasting Performance in Demanding Environments

News 2025-11-17

Durable plastic battery boxes have become a core element in modern automotive power systems, protecting high-value batteries while supporting compact vehicle layouts. By combining mechanical strength, chemical resistance, and smart design, these enclosures help extend battery life, reduce maintenance, and safeguard surrounding electronic components. Their performance directly influences driving range in EVs, cold-start capability in conventional vehicles, and the reliability of advanced onboard electronics.

Key Roles and Application Scenarios in Vehicles

Battery boxes made from engineered plastics are used in passenger cars, commercial trucks, buses, off‑highway machinery, and emerging electric two‑wheelers. In traditional vehicles, they shield 12 V or 24 V lead‑acid batteries from road debris, moisture, and oil contamination. In hybrid and battery electric vehicles, larger plastic housings accommodate high‑voltage lithium‑ion packs, integrating cable routing, vent channels, and mounting points for battery management systems. Under‑hood installations require resistance to heat and engine vibrations, while under‑floor or rear‑mounted packs demand robust impact and splash protection. In harsh environments such as mining, logistics fleets, and agricultural equipment, durable plastic battery boxes minimize downtime by preventing premature battery failures.

Material Properties and Performance Advantages

Automotive battery boxes typically use high‑performance plastics such as polypropylene (PP), glass‑fiber‑reinforced polyamide (PA), or impact‑modified ABS. These materials maintain structural integrity over wide temperature ranges, from winter cold starts to high under‑hood temperatures. Their inherent corrosion resistance eliminates rust issues common with metal enclosures, even when exposed to battery acid, road salt, or cleaning chemicals. Low density reduces overall vehicle weight, supporting fuel efficiency and extended EV range. Advanced formulations offer high dielectric strength, providing electrical insulation between cells and conductive vehicle structures. Controlled stiffness and impact resistance help the enclosure absorb shocks during pothole impacts or minor collisions, protecting internal cells from mechanical stress.

Design Features That Extend Battery Life

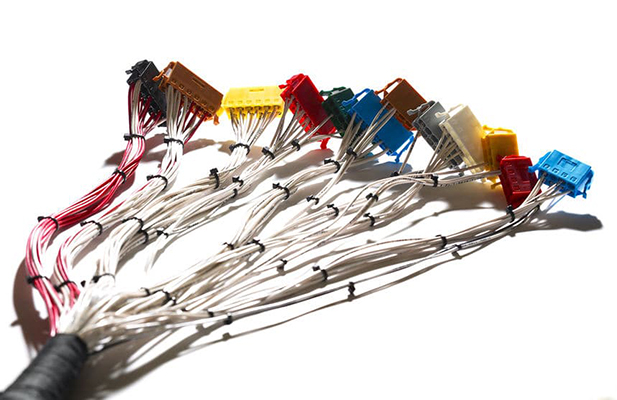

Durable plastic battery boxes allow precise, application‑specific design features that enhance long‑term battery performance. Reinforced ribs and optimized wall thickness prevent deformation under clamping forces and vibration, securing the battery firmly in place. Integrated venting concepts manage gas release from lead‑acid batteries, reducing the risk of pressure build‑up and corrosion around terminals. Drain channels and well‑designed seals keep water out while allowing condensation to escape, preventing moisture‑related leakage paths. Fire‑retardant grades can slow flame spread around high‑energy packs, offering additional protection for surrounding electronic control units. Molded-in cable guides, connector interfaces, and sensor mounts simplify system integration and improve assembly efficiency in high‑volume production.

Integration with Modern Electronic and Thermal Systems

As vehicles incorporate more electronics, the plastic battery box becomes an active system component rather than a simple container. Mounting interfaces for battery management system PCBs, temperature sensors, and current shunts can be molded directly into the housing, reducing wiring complexity and improving signal integrity. For high‑voltage EV packs, the enclosure must coordinate with thermal management systems, accommodating coolant channels, phase‑change materials, or air ducts to keep cell temperatures within a narrow window. The plastic material must withstand repeated thermal cycling without cracking or warping. In connected and autonomous vehicles, stable power delivery from a well‑protected battery is vital to keep advanced driver assistance systems, telematics units, and safety‑critical controllers operating under all road conditions.

Quality, Compliance, and Long-Term Durability

To ensure consistent performance, automotive plastic battery boxes are validated according to stringent OEM and international standards. Typical tests include vibration endurance, thermal shock, chemical exposure, and mechanical impact. Material traceability, dimensional accuracy, and tight process control in injection molding are crucial for maintaining sealing performance and mounting precision. UV‑stabilized grades protect enclosures installed near exterior body panels from long‑term sunlight exposure. When correctly specified and tested, durable plastic housings can match or surpass the service life of the vehicle, supporting extended warranties for batteries in electric and hybrid models while reducing total cost of ownership for fleet operators.

1What are the main benefits of plastic battery boxes over metal enclosures?

Plastic battery boxes offer lower weight, superior corrosion resistance, flexible design options, and improved electrical insulation, which collectively support longer battery life and more efficient vehicle packaging.

2In which vehicles are durable plastic battery boxes most commonly used?

They are widely used in passenger cars, commercial trucks, buses, construction equipment, agricultural machinery, and all types of hybrid and battery electric vehicles.

3How do plastic battery boxes contribute to safety in electric vehicles?

They provide robust mechanical protection, electrical insulation, controlled venting, and integration with thermal management systems, helping to reduce the risk of short circuits, thermal runaway propagation, and damage to nearby electronics.