Tailored Wire Harness Configurations for Modern Automotive Manufacturing

News 2025-10-31

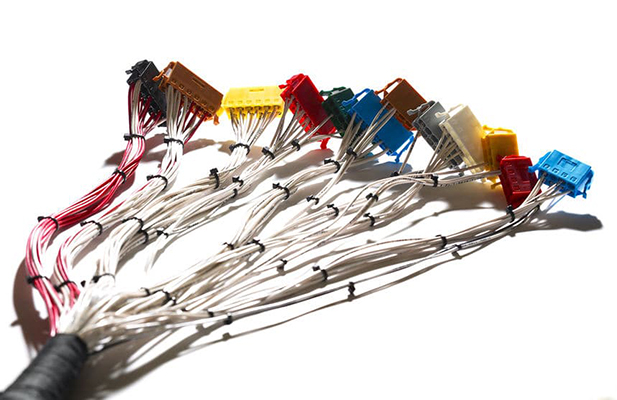

Wire harnesses are indispensable in contemporary automotive manufacturing, forming the intricate web that links sensors, actuators, and control units. With the rapid evolution of vehicle technologies, including hybridization and connectivity, customized wire harness configurations have become essential. These bespoke designs are crafted to fit specific models, incorporating features that enhance electrical performance, reduce material waste, and support sustainable manufacturing practices. By addressing the unique demands of modern vehicles, tailored harnesses contribute to overall system integrity and innovation.

Application Scenarios

In various automotive contexts, tailored wire harnesses play pivotal roles. For electric cars, they manage the high-power demands of batteries and motors, ensuring efficient and safe energy flow. In self-driving cars, custom harnesses integrate a multitude of sensors and AI components, facilitating seamless communication for features like adaptive cruise control. Furthermore, in standard passenger vehicles, they support entertainment and navigation systems, providing reliable connections that enhance user experience.

Performance Advantages

Custom configurations bring forth numerous benefits, such as increased reliability through the use of corrosion-resistant materials and precise routing. This reduces the likelihood of faults, thereby decreasing warranty claims and maintenance expenses. Additionally, by minimizing wire length and optimizing layouts, weight savings are achieved, which improve fuel efficiency and lower carbon footprints. The adaptability of tailored harnesses also allows for easier upgrades and modifications in vehicle designs.

Frequently Asked Questions

1. What is the main purpose of a wire harness?

It bundles and organizes wires to transmit power and data safely within automotive systems.

2. How do tailored designs enhance vehicle efficiency?

They optimize component placement and material use, reducing energy loss and improving overall system performance.

3. What industries benefit most from these configurations?

Automotive sectors focusing on EVs, autonomous tech, and high-end models see significant gains in reliability and innovation.