Battery Box Performance Cars Support High Output Batteries For Demanding Applications

News 2025-11-17

High-performance battery boxes are becoming a core component in the evolution of performance cars, electric conversions, and track-focused hybrids. As power demands rise, these enclosures must support high-output batteries while maintaining safety, thermal stability, and serviceability. A well-engineered battery box protects cells from vibration, impacts, and moisture, while also providing the electrical interfaces needed for rapid power delivery and data monitoring.

Structural Design and Safety Performance

A performance-oriented battery box for high-output batteries starts with a rigid mechanical structure. Typically built from aluminum alloys or high-strength steel, the enclosure must withstand chassis flex, curb impacts, and repeated high-G load events during acceleration, braking, and cornering. Integrated reinforcement ribs, crush zones, and fire-resistant barriers help isolate cells in case of thermal runaway. Sealed gaskets and IP-rated connectors protect the battery pack from dust, water spray, and road debris, which is crucial for track use and harsh weather conditions. Mounting points are engineered to distribute load evenly into the vehicle frame, reducing stress concentrations that could damage the enclosure or the cells inside.

Thermal Management for High-Output Operation

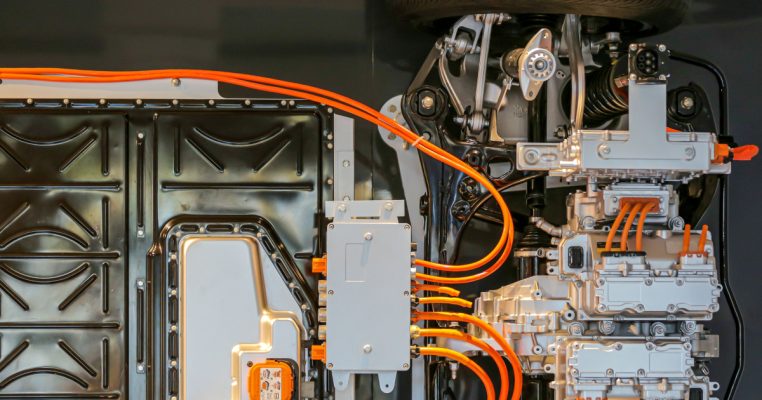

High-output batteries generate significant heat during rapid charge and discharge cycles, especially in performance cars running repeated launch-control events or long track sessions. The battery box must therefore act as a thermal management platform. Designs often include integrated liquid cooling channels, high-conductivity base plates, and optimized airflow paths to keep cell temperatures within a narrow operating window. Stable thermal conditions extend cycle life, maintain consistent power delivery, and prevent power derating triggered by overheating. Temperature sensors positioned throughout the box feed data to the vehicle’s battery management system, enabling predictive control of cooling pumps, fans, and power limits.

Electrical Integration and Monitoring Features

To fully support high-output batteries, the battery box must deliver low-resistance electrical connections and robust signal interfaces. Busbars are engineered with optimized cross-sectional area and materials to minimize I²R losses during peak current events, such as full-throttle acceleration or regenerative braking at high speeds. High-voltage connectors with keyed interfaces and interlock pins improve safety during installation and service. Inside the enclosure, provisions for current sensors, voltage taps, and isolation monitoring devices allow precise supervision of each cell group. These features help detect imbalance, insulation faults, or abnormal current flow before they impact performance or safety.

Application Scenarios in Performance and Motorsport Vehicles

In performance road cars, a compact battery box is often installed under the floor or within the central tunnel to lower the center of gravity and improve weight distribution. For motorsport applications, modular battery boxes make it possible to swap packs quickly between sessions, allowing teams to tailor capacity and output to different tracks. Electric drag racing vehicles use enclosures designed for extreme peak currents and very short duty cycles, emphasizing busbar robustness and high-voltage insulation. Off-road performance vehicles benefit from reinforced housings with additional sealing and underbody protection plates. Across these scenarios, the battery box becomes a key enabler of acceleration performance, consistent lap times, and extended drivetrain durability.

Q&A on Battery Boxes for Performance Cars

1. How does a battery box affect vehicle performance?

A well-designed battery box improves power delivery, thermal stability, and weight distribution, allowing performance cars to sustain higher output without triggering thermal limits or compromising safety.

2. Why is thermal management inside the battery box so important?

Effective thermal management keeps cell temperatures within the optimal range, which preserves capacity, maintains high discharge capability, and reduces the risk of thermal runaway during demanding driving.

3. What features should engineers prioritize when selecting a battery box?

Engineers should focus on structural strength, IP-rated sealing, low-resistance busbars, robust high-voltage connectors, and integrated sensing options that support advanced battery management and motor control systems.