Heavy-Duty Inline Fuse Holder Designed to Safeguard Electrical Circuits in Trucks Trailers and Winch Wiring Applications

News 2026-01-12

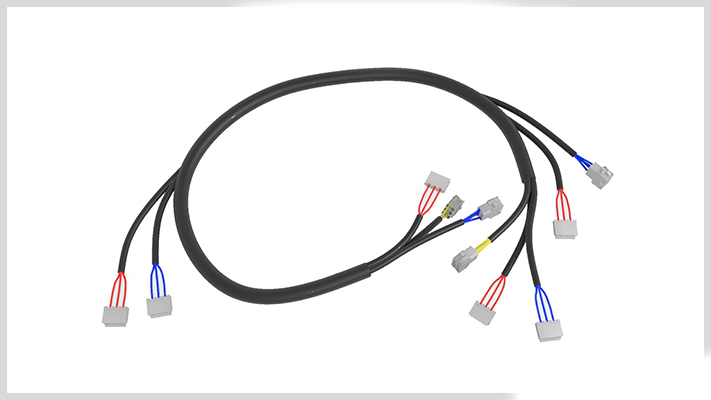

Inline fuse holders play a vital role in safeguarding electrical systems on heavy vehicles. These enclosures secure standard automotive fuses and protect wiring harnesses from overcurrent events that can damage components or start fires. By isolating the fuse element in a sealed housing, inline holders reduce exposure to moisture, dust, and vibration. They are crucial in environments where trucks face rugged terrain or power sensitive electronics.

Application Scenarios

Inline fuse holders serve truck, trailer, and winch wiring systems in demanding conditions. They protect motor circuits on towing rigs and safeguard lighting arrays, brake controllers, and power outlets. In off-road and agricultural vehicles, they ensure reliable operation of hydraulic pumps and electronic controls. Marine and commercial fleets use corrosion-resistant models rated for wet surroundings.

Performance Advantages

Built from rugged polymer and fitted with plated metal contacts, heavy-duty inline fuse holders resist impact, corrosion, and thermal stress. They support a broad range of amperage, from low-current signal protection to high-current power feeds. IP65 or higher sealing prevents water and debris ingress, ensuring consistent function. Quick-release designs allow rapid fuse changeouts, minimizing service downtime.

Installation and Maintenance

Ensure fuse amperage matches wire gauge and load, then mount the holder using brackets or cable ties to minimize vibration. Route wiring away from sharp edges and heat sources to extend service life. Inspect seals and terminals regularly. Tool-free cap removal enables fast fuse swaps, simplifying upkeep and guaranteeing ongoing protection.

1、Choosing Correct Fuse Rating

Match the fuse amperage to the wire gauge and maximum circuit load, incorporating a safety margin of 25%.

2、Materials and Corrosion Resistance

Select fuse holders made from UV-stable polymer and plated terminals to withstand moisture and chemical exposure.

3、Compatibility with Marine Environments

Ensure holders meet marine-grade standards such as IP67 to guarantee reliable operation in wet or saltwater conditions.