Heavy-Duty Wire Harness Components for Semi-Truck and Trailer Electrical Systems

News 2025-10-31

Heavy-duty wire harness components are vital for the reliable operation of electrical systems in semi-trucks and trailers, where durability and performance are non-negotiable. These assemblies integrate wires, connectors, and terminals to handle power distribution, lighting, and advanced control systems. In the demanding world of commercial trucking, they must endure constant vibration, extreme temperatures, and exposure to harsh elements like road salts and fuels. By ensuring secure connections and minimizing electrical failures, these components enhance vehicle safety and efficiency, supporting features such as GPS tracking and automated diagnostics that are increasingly common in modern fleets.

Essential Components and Their Roles

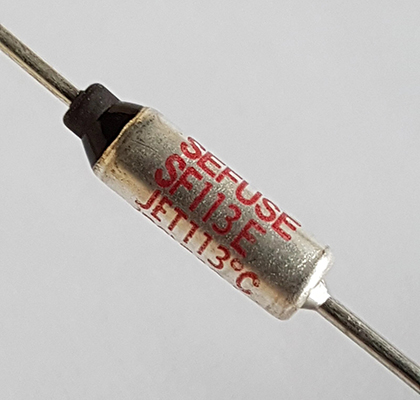

Wire harnesses comprise key elements like high-strand copper wires for superior conductivity and flexibility, corrosion-resistant connectors to withstand moisture, and robust insulation materials that protect against abrasion and heat. These components are engineered for specific functions, such as managing high-current loads in engine compartments or delicate signal transmission in control modules. Performance benefits include reduced energy loss through low-resistance connections and enhanced reliability in high-vibration environments, which are critical for preventing downtime in long-haul operations and ensuring consistent electrical performance under stress.

Real-World Applications in Heavy Vehicles

In semi-trucks and trailers, wire harness components are deployed in diverse scenarios, including powering essential safety features like brake lights and turn signals, as well as supporting auxiliary systems such as refrigeration units and hydraulic lifts. They excel in challenging conditions, such as arctic cold or desert heat, by maintaining integrity and functionality. This resilience translates to tangible advantages, like fewer maintenance interruptions and improved fuel efficiency through optimized electrical systems that reduce parasitic draws, ultimately contributing to cost savings and extended vehicle service life in rigorous transportation settings.

Frequently Asked Questions

1. What materials are typically used in these wire harnesses?

Heavy-duty wire harnesses often incorporate copper conductors for optimal electrical performance and synthetic insulations like PVC or TPE for resistance to environmental factors.

2. How do they enhance vehicle reliability?

By providing secure, vibration-resistant connections, these components minimize the risk of electrical faults, ensuring consistent operation even in prolonged, demanding use cases.

3. What should be considered for installation and maintenance?

Factors include matching the harness to specific vehicle specifications, regular inspections for wear, and using manufacturer-recommended tools to maintain peak performance and longevity.