Industrial Wire Harness Designs for Lawn and Garden Equipment Electrical Systems

News 2025-10-31

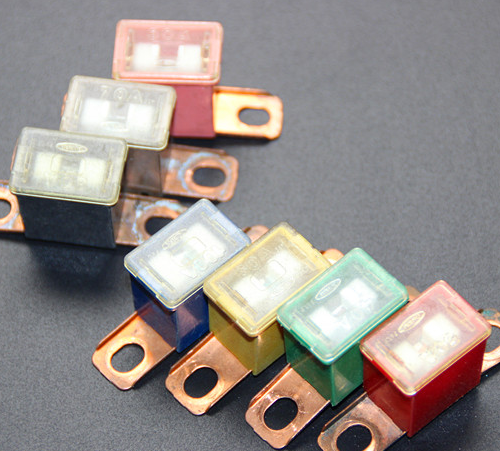

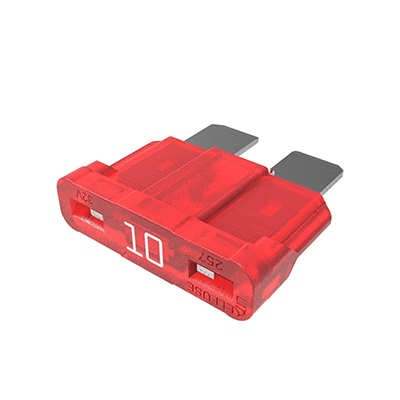

In the field of lawn and garden equipment, electrical systems are essential for driving components like motors, lights, and controls. Industrial wire harness designs provide the backbone for these systems, offering organized wiring that enhances functionality and longevity. These harnesses are specifically engineered to endure outdoor challenges, including exposure to rain, dirt, and physical impacts, ensuring that equipment such as mowers and trimmers operate efficiently and safely. By integrating multiple wires into a single assembly, wire harnesses reduce the risk of disconnections and simplify installation, making them a vital element in modern landscaping tools.

Application Scenarios

Wire harness designs find extensive use in various lawn and garden applications. For example, in riding lawn mowers, they connect the battery to the starter motor and electronic dashboards, facilitating smooth starts and responsive controls. In portable devices like hedge trimmers or blowers, compact harnesses manage power delivery in confined spaces while withstanding repeated handling and vibrations. Designers focus on attributes such as water resistance and flexibility to suit these environments, which helps in maintaining performance during extended use in gardens, parks, and commercial landscapes, ultimately supporting reliable operation under diverse conditions.

Performance Advantages

Optimized wire harness designs deliver significant benefits in terms of durability and efficiency for lawn equipment. They employ robust materials that resist corrosion and abrasion, extending the lifespan of electrical systems exposed to elements like sunlight and moisture. These designs also minimize weight and space requirements, allowing for more compact and maneuverable tools without compromising power output. Additionally, by reducing the number of individual connections, harnesses lower the potential for faults, leading to fewer breakdowns and easier troubleshooting, which translates to cost savings and higher productivity for users in both residential and professional settings.

Frequently Asked Questions

1. What factors influence wire harness design for outdoor equipment?

Key factors include environmental exposure, such as UV radiation and temperature extremes, as well as mechanical stresses like vibration and bending, which dictate material selection and layout to ensure long-term reliability.

2. How do wire harnesses contribute to energy efficiency in garden tools?

By organizing wiring to reduce resistance and heat loss, wire harnesses improve current flow, enabling more efficient energy use and extending battery life in cordless models commonly used in lawn maintenance.

3. Why are custom wire harnesses important for specific equipment types?

Custom designs allow for precise fit and function tailored to unique equipment layouts, enhancing integration with components like sensors or controllers, and ensuring compliance with safety standards in varied garden applications.