License Plate Light Fuse Safeguards License Plate Illumination Circuits In Automotive Systems

News 2025-11-17

License plate light fuse safeguards license plate illumination circuits in demanding automotive environments by isolating faults and preventing wiring damage. Integrated into the exterior lighting harness, this small component maintains continuous plate visibility required by traffic regulations while protecting adjacent systems such as tail lamps, turn signals, and body control modules. By limiting fault current and localizing failures, it supports long-term electrical stability, lower maintenance costs, and consistent vehicle safety performance.

Role of the License Plate Light Fuse in Vehicle Electrical Architecture

The license plate light fuse sits between the vehicle power distribution unit and the plate illumination lamps, acting as a dedicated overcurrent barrier. When corrosion, vibration-induced wiring damage, or moisture ingress causes a short circuit, the fuse element melts in a controlled manner, opening the circuit before upstream components are stressed. This behavior protects harness insulation, lamp holders, connectors, and PCB traces in lighting control modules. In modern vehicles using multiplexed networks and centralized body controllers, isolating faults to the small license plate branch helps technicians diagnose issues quickly and reduces downtime in fleet applications.

Key Performance Characteristics and Safety Benefits

Performance of the license plate light fuse is defined by its current rating, voltage rating, time-current curve, and breaking capacity. Proper coordination with the lamp load ensures normal operating current passes without nuisance opening, while abnormal surges caused by wiring shorts trigger rapid interruption. High breaking capacity is necessary to safely clear faults in 12 V and 24 V systems that can deliver substantial short-circuit current from the battery. Stable resistance, minimal aging, and tight tolerance of melt characteristics support predictable protection over the vehicle lifetime. These parameters help prevent overheating, reduce fire risk near the rear bumper area, and maintain compliance with lighting safety standards.

Application Scenarios in Passenger, Commercial, and Specialty Vehicles

The license plate light fuse is widely used in passenger cars, SUVs, pickup trucks, commercial vans, trailers, buses, and specialty vehicles such as emergency or municipal fleets. Rear lamp assemblies often integrate LED license plate modules that require precise overcurrent protection due to their low power consumption and sensitivity to voltage spikes. In commercial vehicles operating long hours, the fuse must withstand frequent on-off cycles, harsh temperature variations, road contaminants, and mechanical shock. Properly selected fuses enable modular rear lighting systems where each functional zone, including license plate illumination, can be isolated and serviced independently, improving uptime for logistics and public transport operators.

Selection, Integration, and Maintenance Considerations

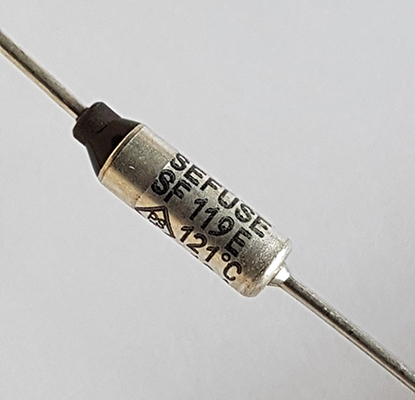

Engineering teams choose license plate light fuses by analyzing steady-state lamp current, inrush characteristics, wiring gauge, and expected ambient temperatures within the rear lamp cavity or fuse box. Standard blade, mini-blade, and micro blade formats simplify integration into automotive fuse panels, while sealed holders support installation in exposed chassis locations. During maintenance, using the specified rating is critical; overspecifying the fuse may allow wiring damage, whereas underspecifying causes nuisance openings and customer complaints. Clear labeling, accessible fuse locations, and diagnostic information in service manuals help workshops quickly restore license plate illumination while ensuring protective performance remains intact.

1、Why is a dedicated fuse needed for license plate lights?

A dedicated fuse localizes faults in the license plate lighting branch, preventing damage to the main rear lighting harness and maintaining functionality of other safety-critical lamps.

2、How do LED license plate modules affect fuse selection?

LED modules draw lower current yet can be sensitive to surge conditions, so engineers often specify lower current ratings and fast-acting characteristics to match the electronic driver behavior.

3、What symptoms indicate a license plate light fuse problem?

Typical symptoms include an unlit plate area while other rear lamps operate normally, repeated lamp outages after replacement bulbs, or visual evidence of a blown fuse in the rear or cabin fuse panel.