Long-Term-Stability Thermal Fuse Maintains Performance Over Extended Use In Demanding Circuits

News 2025-11-27

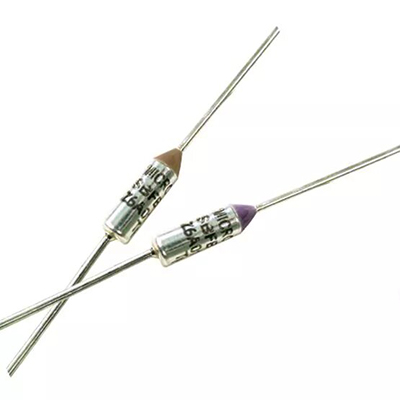

Long-term-stability thermal fuse maintains performance over extended use in demanding circuits by delivering predictable cutoff temperature, consistent resistance, and dependable mechanical integrity. As electronic systems move toward higher power density and miniaturization, thermal protection components must endure thousands of heating and cooling cycles without drift. This type of fuse is designed to interrupt current when a preset temperature is reached, protecting semiconductors, wiring, and batteries from thermal runaway and catastrophic failure.

Key Performance Characteristics Of Long-Life Thermal Fuses

Long‑term‑stability thermal fuses use carefully selected fusible alloys and crystalline encapsulation materials to maintain a narrow opening temperature tolerance, typically within ±3–5 °C over their service life. Low initial contact resistance helps minimize self‑heating and improves system efficiency, especially in high-current power supplies and motor drives. Robust lead welding and hermetic or semi‑hermetic sealing prevent moisture ingress, which can otherwise shift the trip point or cause premature aging. These devices are tested under accelerated thermal cycling and high‑humidity conditions to verify that their electrical and thermal properties remain stable after years of field operation.

Application Scenarios In Industrial And Consumer Electronics

In industrial motor control, a long‑term‑stability thermal fuse is commonly installed in series with stator windings or control transformers, where it guards against blocked rotor conditions, ventilation failure, or ambient temperature spikes. Power tools, vacuum cleaners, and HVAC blowers use these fuses to prevent coil overheating and insulation breakdown. In consumer electronics, such as AC adapters, gaming consoles, and set‑top boxes, the fuse is typically placed near primary switching MOSFETs, transformers, or hot spots on the PCB to limit damage under overload or abnormal operation. Energy‑storage and battery‑powered systems deploy thermal fuses near cell groups or DC‑DC converters to mitigate risks related to high charge currents, short circuits, and enclosure hot spots.

Performance Advantages Over Conventional Protection Devices

Compared with standard one‑shot thermal links or resettable PTC devices, long‑term‑stability thermal fuses offer tighter temperature accuracy, reduced long‑term drift, and higher resistance to mechanical shock and vibration. Their defined, single‑event opening behavior prevents nuisance tripping in equipment that naturally experiences frequent thermal cycling, such as power inverters, LED drivers, and office printers. The compact axial or radial package options simplify PCB layout and facilitate integration close to heat sources, improving sensing fidelity. High interrupt ratings and UL/IEC certifications support use in mains‑connected applications, while compliance documentation assists engineers during safety approval and EMC testing.

Design-In Considerations And Integration Practices

To extract maximum benefit from a long‑term‑stability thermal fuse, engineers must coordinate electrical rating, opening temperature, and physical placement. The fuse should be thermally coupled to the monitored component using clips, adhesive sleeves, or direct winding integration, while avoiding excessive mechanical stress on the leads. Proper coordination with upstream circuit breakers, NTC inrush limiters, and overvoltage protection ensures that the fuse acts as the last line of defense rather than a routine protective element. Simulation of worst‑case ambient conditions, airflow loss, and fault scenarios helps validate that the fuse will operate within its specified envelope across the expected lifetime of the equipment.

1. What industries benefit most from long-term-stability thermal fuses?

They deliver strong value in industrial automation, home appliances, HVAC equipment, battery systems, and high‑density power supplies where long service life and tight temperature control are required.

2. How does placement affect fuse performance in real applications?

Mounting the fuse close to the primary heat source and ensuring good thermal contact greatly improves response accuracy and prevents both delayed activation and unnecessary opening.

3. Are these thermal fuses compatible with automated manufacturing?

Most long‑term‑stability thermal fuses are available in standardized lead forms suitable for automatic insertion, and their robust construction tolerates typical soldering profiles when specified limits are observed.