Precision Wire Harness Assemblies for Enhanced Automotive Headlight and Taillight Performance in Various Driving Conditions

News 2025-10-31

Wire harness assemblies are crucial components in modern automotive systems, particularly for headlight and taillight electricals. These assemblies ensure reliable connectivity and power distribution, which are essential for safe and efficient vehicle operation. In the automotive industry, they play a key role in integrating complex electrical systems, supporting features like adaptive lighting and signal integrity. By focusing on high-quality manufacturing, these assemblies help prevent failures that could lead to safety issues or downtime. As vehicles evolve with advanced electronics, understanding the role of wire harnesses in headlight and taillight applications becomes vital for engineers and manufacturers alike.

Application Scenarios

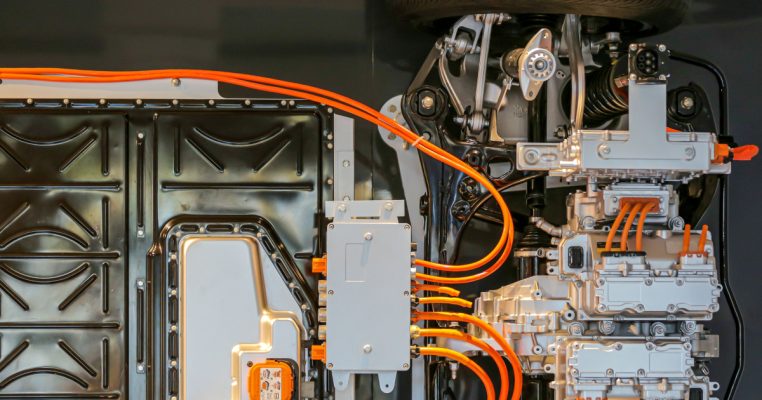

Wire harness assemblies find extensive use in various automotive contexts, from everyday commuter vehicles to high-performance sports cars. In headlight systems, they connect bulbs, sensors, and control units to manage beam patterns and brightness levels, enhancing visibility during night driving or adverse weather. For taillight electricals, these assemblies support functions like brake lights, turn signals, and reverse indicators, ensuring quick response times and regulatory compliance. Additionally, in electric and hybrid vehicles, wire harnesses integrate with energy management systems, facilitating energy-efficient lighting that reduces overall power consumption and extends battery life.

Performance Advantages

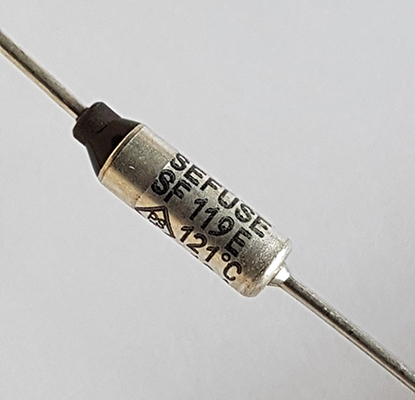

The design of wire harness assemblies offers significant benefits, including superior durability and resistance to environmental factors. Constructed with high-temperature resistant materials, they withstand extreme conditions such as heat, vibration, and moisture, which are common in automotive settings. This enhances longevity and reduces maintenance needs, leading to cost savings over the vehicle’s lifecycle. Moreover, optimized layouts minimize electrical resistance and signal loss, improving energy efficiency and performance in lighting systems. These advantages not only boost safety by ensuring consistent operation but also support compliance with stringent industry standards, making them indispensable for reliable automotive electricals.

Common Questions

1. What are the key materials in wire harness assemblies?

Common materials include copper for conductors and PVC or silicone for insulation, chosen for their conductivity and resistance to wear.

2. How do wire harnesses improve automotive safety?

They ensure secure connections that prevent short circuits, maintaining proper function of headlights and taillights for better visibility and signaling.

3. What factors affect the lifespan of these assemblies?

Exposure to heat, chemicals, and mechanical stress can impact durability, but quality manufacturing and proper installation extend their life significantly.