Quick-Response-Time Thermal Fuse Limits Damage From Sudden Temperature Spikes In Electronics Systems

News 2025-11-27

Quick-response-time thermal fuses are engineered to interrupt current within milliseconds once abnormal heat is detected, limiting damage from sudden temperature spikes in densely packed electronic systems. By combining precise melting-point alloys with low thermal mass structures, these fuses act as sacrificial protectors that permanently open the circuit when preset temperature thresholds are exceeded. This function is increasingly important in high-power, miniaturized designs where localized overheating can rapidly escalate into catastrophic failure, smoke, or fire.

Key Operating Principles And Construction

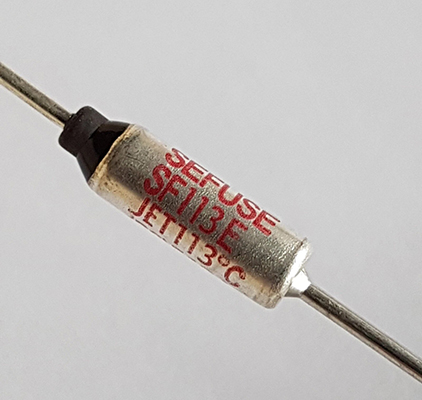

Quick-response thermal fuses integrate a temperature-sensitive pellet or alloy in series with the load. Under normal conditions, the element maintains low resistance and carries rated current without significant self-heating. When the surrounding temperature rises beyond the calibrated trip point, the alloy melts or deforms, causing spring pressure or mechanical separation to open the contacts. Because the sensing element is in direct thermal contact with the monitored surface or air stream, response time is significantly faster than that of standard fuses that rely primarily on overcurrent heating. Designers can select from radial, axial, or surface-mount packages, with hold temperatures spanning consumer appliances, industrial drives, EV battery modules, LED drivers, and telecom power shelves.

Performance Advantages In Demanding Applications

The main advantage of quick-response thermal fuses lies in their ability to act during fast transient events before PCB substrates, wiring harnesses, or plastic housings reach ignition temperatures. Accurate trip temperature tolerances enable tight coordination with control IC protection algorithms and system derating curves. Low internal resistance minimizes power loss and heat rise under normal load, supporting high efficiency in compact power supplies, chargers, and inverters. These fuses are inherently fail-safe: once activated, they remain open, providing a clear indication that the protected device has experienced abnormal thermal stress and should be inspected or replaced rather than automatically reset.

Typical Use Cases Across Industry Sectors

In consumer electronics, quick-response thermal fuses are widely used in AC adapters, hair dryers, coffee makers, and induction cookers, addressing risks associated with airflow blockage, thermostat failure, or user misuse. In industrial automation, they protect motor windings, transformers, and switching power modules exposed to ambient temperature swings and mechanical overload. Battery-powered systems, including e-bikes and handheld tools, benefit from thermal fuses mounted near cells and MOSFET arrays to mitigate sudden runaway conditions. LED lighting drivers incorporate them near electrolytic capacitors and high-density drivers to prevent heat-induced degradation, extending product lifetime and maintaining lumen output stability.

Design Selection, Standards Compliance And Integration

When specifying a quick-response thermal fuse, engineers must balance rated current, operating temperature, cutoff temperature, and safety approvals such as UL, VDE, and IEC standards. Correct placement is crucial: the fuse should be thermally coupled to the hottest potential spot, yet electrically isolated according to creepage and clearance rules. PCB designers often place thermal vias or copper pads beneath the fuse body to optimize heat transfer from power components. Coordinating the fuse rating with overcurrent devices, NTC thermistors, and system firmware ensures layered protection. Manufacturers also provide derating curves that help predict lifetime performance in high-humidity or high-vibration environments.

FAQs About Quick-Response Thermal Fuses

1. Where are quick-response thermal fuses most commonly used?

They are widely used in power adapters, household appliances, LED drivers, motor drives, and battery packs wherever rapid temperature spikes may occur.

2. How does a thermal fuse differ from a standard current fuse?

A thermal fuse responds to excessive temperature rather than only to overcurrent, opening the circuit once a calibrated temperature threshold is reached.

3. Can a quick-response thermal fuse be reset after activation?

No, it is a one-time protective component; once it opens, the fuse must be replaced to restore operation.