Robust-Build Thermal Fuse Ensures Safety Across Harsh Automotive Duty Cycles

News 2025-11-27

Robust-build thermal fuses are becoming a core safety element in modern vehicles that operate under severe mechanical, thermal, and electrical stress. From compact passenger cars to heavy-duty commercial trucks, these protection devices interrupt current when abnormal temperatures threaten wiring harnesses, power electronics, or battery systems. By combining precise opening characteristics with rugged construction, the thermal fuse safeguards circuit integrity while supporting long service life in demanding environments such as engine compartments, underfloor battery trays, and transmission control modules.

Key Operating Principles and Design Structure

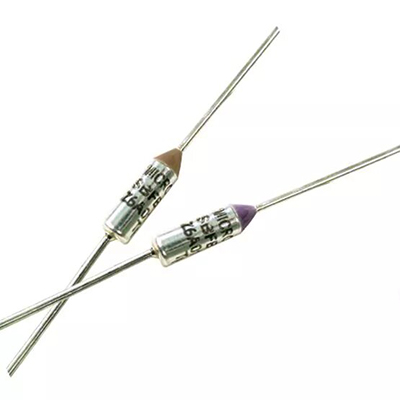

The robust-build thermal fuse integrates a calibrated thermal pellet, spring mechanism, and conductive terminals inside a sealed, vibration-tolerant housing. During normal operation, the pellet maintains mechanical pressure that keeps the circuit closed. When ambient or component temperature rises beyond a defined threshold, the pellet melts, releasing the spring and permanently opening the circuit. This one-time protective action prevents overheating of coils, relays, inverters, and chargers. Automotive versions feature enhanced creepage distances, high-voltage insulation, and lead materials designed to withstand repetitive thermal cycling without mechanical fatigue.

Performance Benefits Under Rigorous Vehicle Conditions

Within the automotive sector, this fuse type stands out through tight trip accuracy, high interrupt ratings, and proven resistance to vibration, shock, and contamination. Stable operating points help engineers coordinate protection levels with MOSFETs, IGBTs, and electronic control units, limiting nuisance openings while still reacting quickly to fault conditions. Metal housings and high-temperature encapsulants support continuous exposure to under-hood temperatures and hot spots near turbochargers or exhaust components. Salt spray, dust, fuel vapor, and humidity do not easily degrade internal contact surfaces, supporting consistent performance over the full vehicle lifetime.

Application Scenarios in Modern Electric and Conventional Vehicles

Robust-build thermal fuses appear in traction battery packs, on-board chargers, DC/DC converters, HVAC blowers, and seat-heating circuits. In hybrid and battery-electric platforms, they help prevent thermal runaway in densely packed cell modules and busbar assemblies by cutting off current during abnormal heating events. In 12 V and 48 V architectures, the device protects alternators, starter-generators, and power distribution boxes from localized overheating caused by overload, connector degradation, or wiring faults. Parking cameras, infotainment units, and ADAS modules also benefit from localized thermal protection, which contributes to higher safety ratings and fewer field failures.

Integration, Compliance, and Selection Considerations

Circuit designers select these fuses based on rated current, opening temperature, interrupt capability, and mechanical format, such as axial leaded or surface-mount packages. Automotive versions comply with AEC-Q200 test regimes, ISO thermal shock profiles, and OEM-specific vibration specifications, simplifying qualification in global platforms. Compact footprints support dense PCB layouts in control units, while larger bolt-down styles suit high-current power rails. Early coordination with thermal simulations and hardware tests helps engineers position the fuse close to the primary heat source, minimizing response time and ensuring consistent operation under all load conditions.

1. Typical operating temperature range

Many automotive thermal fuses activate between 72°C and 240°C, selected according to the surrounding component limits and safety margins defined by the vehicle platform.

2. Suitability for high-voltage EV systems

Yes. Specialized versions support high-voltage traction systems, pairing enhanced insulation distances and elevated interrupt ratings to meet EV safety requirements.

3. Replacement and service approach

Because the device is a one-shot protection element, replacement occurs during service if the fuse has opened. Proper root-cause analysis is recommended to confirm the underlying thermal fault before installing a new unit.