Slow-Blow Fuse Technology Enabling Stable High-Inrush Motor Startup Circuits

News 2025-11-17

Slow-blow-type fuse gradual response protects motor startup circuits by addressing the recurring challenge of high inrush current. When an induction motor or compressor first energizes, the current can spike several times above its rated value. A fast-acting fuse often interprets this inrush as a fault and opens the circuit, causing nuisance trips, downtime, and unnecessary service calls. Slow-blow fuses, also referred to as time-delay fuses, are engineered to tolerate these short-duration surges while still opening quickly under sustained overloads or faults, making them a cornerstone of modern motor protection design.

Principle of gradual thermal response

Slow-blow fuses incorporate a specially profiled fuse element, sometimes combined with thermal-mass features such as solder blobs or spring mechanisms. This structure slows the heating rate of the element when exposed to brief high current peaks. The I²t characteristic is intentionally higher than that of fast-acting types, meaning the fuse can absorb more energy during startup without melting. Under a genuine fault, however, the element still reaches melting temperature rapidly, clearing the circuit and limiting let-through energy. This gradual thermal response is vital for motors that routinely experience heavy inrush, including HVAC blowers, refrigeration compressors, conveyor drives, and industrial pumps.

Application scenarios in motor startup circuits

Slow-blow fuses are widely applied in single-phase and three-phase motor control panels, soft starters, variable frequency drive input stages, and direct-on-line (DOL) starters. In HVAC systems, they protect fan motors and scroll compressors from short circuits while preventing nuisance tripping during low-temperature starts. In industrial automation, slow-blow types are installed ahead of contactors and overload relays to coordinate protection and ensure predictable clearing during locked-rotor conditions. They are also used in agricultural pumps and small machine tools where power quality may fluctuate, allowing the system to withstand short voltage dips and subsequent current surges without unnecessary fuse replacement.

Performance advantages and coordination benefits

Key performance advantages include superior tolerance to inrush current, reduced downtime, and improved selectivity when coordinated with thermal overload relays or motor protection circuit breakers. By choosing a slow-blow fuse rated close to the motor’s full-load current, designers achieve tight protection while still allowing up to six or eight times inrush, depending on the fuse’s time-current curve. This minimizes oversizing and improves fault discrimination between branch circuits. The controlled let-through energy helps protect winding insulation, contactor tips, and printed circuit boards in electronic controllers. Slow-blow fuses also support global compliance, as many series are certified under UL, IEC, and other regional standards, simplifying adoption in export-oriented equipment.

Selection, sizing, and design considerations

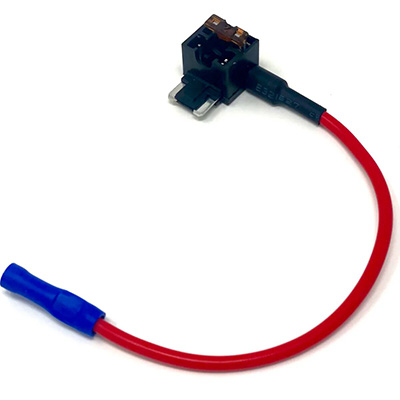

Proper selection requires careful analysis of motor starting profile, line voltage, ambient temperature, and expected fault levels. Engineers typically review manufacturer time-current curves and I²t data to ensure that the fuse does not open during normal start but clears safely within required limits under overload or short circuit conditions. Attention must be paid to fuse holder ratings, creepage and clearance distances, and coordination with upstream breakers to avoid cascade tripping. For compact motor drives, cartridge or surface-mount slow-blow fuses offer high interrupting capacity in limited space, supporting high-density PCB layouts in compressors, pumps, and appliance controllers.

Practical Q&A for motor startup applications

1. Why choose a slow-blow fuse instead of a fast-acting type in motor circuits?

A slow-blow fuse tolerates the high inrush current at motor startup, preventing nuisance tripping while still providing effective protection against sustained overloads and short circuits.

2. How does a slow-blow fuse improve system uptime in HVAC and pump systems?

By allowing normal inrush without opening, it reduces unnecessary service interventions, keeps motors running during frequent starts, and lowers maintenance costs across the equipment lifecycle.

3. What parameters are most important when specifying a slow-blow fuse?

Engineers focus on rated current, voltage, interrupting rating, I²t values, and the time-current curve, ensuring proper coordination with motor characteristics and upstream protective devices.