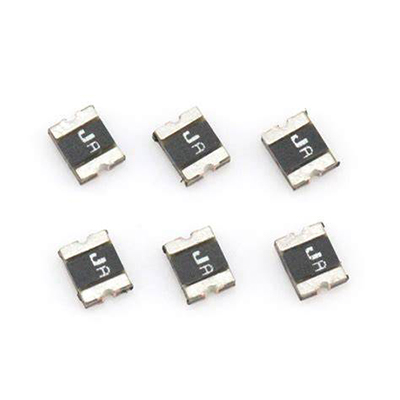

Thermal-Type Fuse Auto Reset Function Reduces Maintenance And Downtime

News 2025-11-17

Thermal-type fuse automatic reset feature eliminates frequent replacements

Operating principle of the resettable thermal fuse

Thermal-type resettable fuses, often referred to as PPTC or polymeric resettable devices, are designed to limit current by using a temperature-sensitive resistive element. Under normal operating conditions, the material exhibits low resistance, allowing current to pass with minimal power loss. When excessive current or elevated ambient temperature pushes the device beyond its trip threshold, the internal polymer matrix heats up, expands, and sharply increases in resistance. This rapid transition effectively limits fault current and protects downstream circuitry. Once power is removed or the fault clears, the material cools and returns close to its original low-resistance state, enabling automatic reset without manual replacement.

Performance advantages over single-use fuses

Compared with one-time thermal fuses that permanently open when triggered, resettable thermal-type fuses significantly reduce service interventions and material waste. Their self-resetting capability translates to fewer spare parts, less downtime, and lower total cost of ownership across the product life cycle. These devices offer stable hold current ratings, precise trip characteristics, and repeatable performance over thousands of cycles when properly dimensioned. Low series resistance helps minimize voltage drop and power dissipation in compact electronics, while fast response to overload conditions helps prevent PCB damage, connector melting, and insulation breakdown. Their behavior is predictable over a broad temperature range, making them suitable for robust, standards-compliant protection concepts.

Key application scenarios in modern electronics

Resettable thermal fuses are widely adopted in consumer electronics, industrial control units, and communication infrastructure where recurring inrush currents and intermittent faults are common. In battery packs, rechargeable tools, and e-mobility accessories, they protect cells and wiring harnesses against short circuits and overcurrent during charging or load transients. In USB hubs, LED lighting drivers, and power adapters, they safeguard ports and controllers from user-induced faults such as cable damage or incorrect connections. Industrial automation systems integrate these components on I/O modules, PLC backplanes, and sensor lines to prevent local failures from propagating across the entire network, supporting higher system availability and easier maintenance.

Design considerations and selection guidelines

Selecting a thermal-type resettable fuse requires careful alignment between hold current, trip current, ambient temperature, and expected fault profile. Engineers typically dimension the hold current above the maximum steady-state load while ensuring that short-circuit or overload conditions reliably trigger the trip state. Thermal derating curves must be evaluated to account for enclosure conditions and neighboring heat sources on densely populated PCBs. Package style, such as radial leaded or surface-mount, affects solder profile, mechanical robustness, and automated assembly. For applications in automotive, telecom, or medical equipment, compliance with relevant safety and quality standards should be verified, including flammability ratings and long-term stability under repeated thermal cycling.

Impact on maintenance strategies and sustainability

Integrating resettable thermal fuses alters maintenance planning by reducing the need for on-site spare parts and manual fuse replacement after overload events. Service teams can focus on diagnosing root causes rather than swapping components, which shortens repair cycles and accelerates system restart. Automatic reset behavior also supports remote systems such as base stations, outdoor LED signage, and smart metering devices, where physical access is limited and truck rolls are costly. From a sustainability perspective, the reuse of a single device over many protection events reduces electronic waste and supports eco-design objectives without compromising safety margins or operational uptime.

1. How does a thermal-type resettable fuse improve equipment uptime?

By automatically returning to a low-resistance state after a fault clears, it restores normal operation without manual intervention, reducing downtime linked to fuse replacement.

2. Where are resettable thermal fuses most commonly used?

They are widely used in battery-powered devices, consumer electronics, LED drivers, USB ports, industrial control modules, and communication equipment that require frequent fault tolerance.

3. What is the main factor when selecting a resettable thermal fuse?

The most important parameter is the relationship between hold current and trip current at the expected ambient temperature, ensuring normal operation while guaranteeing safe interruption during overloads.