Weatherproof Fuse Protective Casing Enhancing Outdoor Electrical Safety and Durability

News 2025-11-17

Weatherproof fuse protective casings are engineered to shield sensitive fuse elements from moisture, dust, and mechanical impact in demanding environments. By enclosing the fuse in a sealed housing, these casings greatly reduce the risk of short circuits, corrosion, and nuisance tripping caused by water ingress or airborne debris. They are widely adopted in outdoor power systems, vehicle wiring harnesses, industrial automation lines, and renewable energy installations where exposure conditions can severely shorten component life.

Key Applications in Harsh Environments

Weatherproof fuse protective casings play a crucial role in outdoor low-voltage distribution panels, street lighting controllers, and traffic signaling cabinets exposed to rain, snow, and road dust. In transportation, they safeguard blade or cartridge fuses used in trucks, construction machinery, marine equipment, and agricultural vehicles that operate in muddy, high-vibration conditions. Photovoltaic combiner boxes and small wind turbine controllers also rely on these casings to prevent condensation and sand intrusion, helping maintain stable protection of DC circuits. Indoor applications include food-processing lines and washdown areas where frequent cleaning sprays can otherwise penetrate unprotected fuse holders.

Performance Features and Protection Mechanisms

A weatherproof fuse protective casing typically combines a robust housing, high-grade sealing system, and secure locking structure. Enclosures are often molded from flame-retardant engineering plastics or corrosion-resistant metal to withstand UV exposure, chemicals, and temperature fluctuations. Gaskets and O-rings form a continuous seal, enabling high IP ratings such as IP65 or IP67 that prevent water jets or temporary immersion from reaching the fuse. Many models integrate strain relief and cable glands to maintain seal integrity around conductors. Snap-lock or screw-fastened covers avoid accidental opening, while transparent windows or indicator caps allow quick visual inspection of fuse status without compromising environmental protection.

Advantages in Safety, Reliability, and Maintenance

By isolating the fuse from moisture and contaminants, these casings reduce insulation breakdown and minimize oxidation on fuse terminals, extending service life and improving contact stability. Enhanced environmental protection lowers the probability of unexpected circuit interruptions, which is crucial in safety-related loads such as emergency lighting, pumps, or communication equipment. Maintenance teams benefit from faster troubleshooting because intact casings prevent corrosion that often complicates fuse removal. Standardized footprints and compatibility with common fuse formats simplify inventory management, while clearly labeled housings support traceability and compliance with electrical safety regulations in industrial and commercial installations.

Selection Parameters and Integration Considerations

When specifying a weatherproof fuse protective casing, engineers should evaluate operating voltage and current, fuse type, and short-circuit capacity of the protected circuit. Environmental parameters such as ambient temperature range, UV intensity, salt spray exposure, and cleaning procedures influence material selection and IP rating. Mounting style is another key factor: panel-mount, DIN-rail, or in-line configurations must match existing layouts and cable routing. Proper torque on sealing glands and correct cable diameter are essential to maintain water and dust resistance throughout the product life cycle. Integration into wire harnesses or junction boxes should also consider accessibility for fuse replacement while preserving the integrity of the sealed enclosure.

Typical Use Cases and Industry Adoption

Utility companies employ weatherproof fuse casings in pole-mounted cabinets and distribution boards to protect critical protection circuits under constant outdoor exposure. In the automotive and off-highway sector, compact sealed fuse blocks prevent splash water and mud from reaching high-current links near batteries and engine compartments. Marine installers choose watertight casings to secure navigation lights, bilge pumps, and communication systems against spray and condensation inside cramped hull spaces. OEMs in building automation integrate these enclosures into rooftop HVAC units and exterior signage controllers to maintain long-term electrical safety and reduce service calls caused by weather-induced failures.

1. What IP rating should be selected for outdoor use?

For most general outdoor applications, an IP65 or IP67 weatherproof fuse protective casing is recommended, ensuring strong protection against dust and high-pressure water exposure.

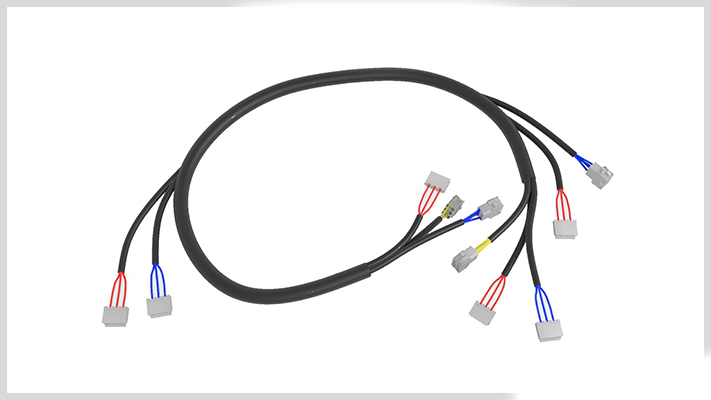

2. Can these casings be used in automotive wiring harnesses?

Yes, sealed in-line or block-style fuse casings are widely used in 12 V and 24 V automotive and off-road harnesses to prevent water, mud, and vibration from damaging fuses.

3. Do weatherproof casings affect fuse replacement time?

When properly specified, they actually simplify maintenance by keeping terminals clean and accessible; technicians only need to open the sealed cover to replace the fuse without dealing with corrosion or debris.