Wire Harnesses Engineered for Heavy-Duty Trucks to Withstand Intense Vibration and Load Demands

News 2025-10-24

In the demanding world of heavy-duty trucking, wire harnesses are essential components that bundle and protect electrical wiring, ensuring seamless operation under extreme conditions. Heavy-duty trucks, used in industries like construction, mining, and freight transport, face constant high vibrations from rough terrains and significant load stresses that can degrade standard wiring. This leads to potential failures in critical systems such as lighting, braking, and engine controls, posing safety risks and increasing maintenance costs. Wire harnesses specifically designed for these environments incorporate robust engineering to maintain reliability, reducing downtime and enhancing overall vehicle performance by addressing the unique challenges of high-vibration and high-load scenarios.

Applications in Challenging Operational Settings

Heavy-duty trucks operate in diverse and harsh environments where wire harnesses must perform flawlessly. For example, in construction sites, vehicles encounter irregular surfaces and heavy impacts, requiring harnesses that resist abrasion and secure connections to prevent dislodgments. In mining operations, exposure to dust, moisture, and extreme temperatures adds complexity, making vibration-resistant designs crucial for maintaining electrical integrity. Similarly, long-haul trucking involves prolonged exposure to road vibrations and dynamic loads, where specialized harnesses support advanced systems like GPS and automated controls. These applications highlight how tailored wire harnesses contribute to operational efficiency and safety in sectors that demand unyielding durability.

Core Performance Benefits and Design Innovations

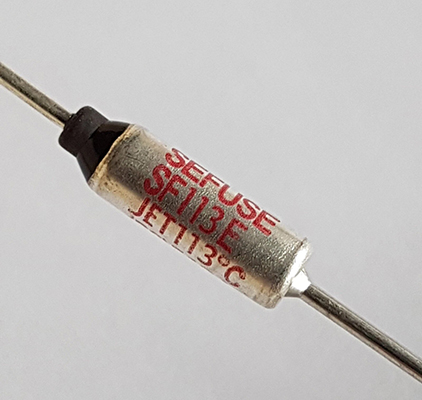

Wire harnesses for high-vibration and load conditions feature advanced materials and construction techniques that deliver superior performance. Utilizing high-grade polymers and reinforced connectors, these harnesses absorb shocks and minimize wire fatigue, extending service life in demanding applications. Design elements such as flexible routing and vibration-dampening mounts reduce the risk of short circuits and connector failures, ensuring consistent electrical flow under stress. This results in enhanced reliability, with studies showing up to 30% fewer failures compared to standard harnesses in similar conditions. By prioritizing load-bearing capacity and vibration resistance, these components not only improve truck longevity but also support compliance with industry standards, fostering safer and more efficient heavy-duty operations.

Frequently Asked Questions

1. What materials are commonly used in these wire harnesses?

They typically incorporate high-strength synthetic materials and corrosion-resistant metals to endure vibrations and loads without compromising flexibility or conductivity.

2. How do these harnesses enhance truck reliability?

By reducing the likelihood of wire breaks and disconnections in harsh conditions, they minimize downtime and maintenance needs, leading to more dependable vehicle performance over time.

3. Are custom designs available for specific truck models?

Yes, manufacturers offer tailored solutions that integrate with particular truck systems, ensuring optimal fit and function in specialized high-vibration environments.