Micro Fuse: Compact and Reliable Overcurrent Protection Solution

Introduction

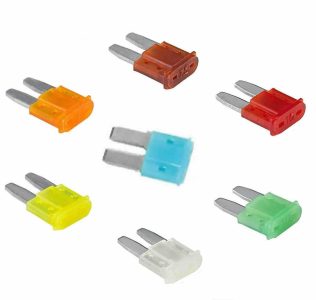

A micro fuse is a small-sized overcurrent protection component designed to safeguard electrical circuits from excessive current flow, preventing device damage and safety hazards. Widely applied in consumer electronics, automotive electronics, medical devices, and industrial control systems, micro fuses feature compact structures, precise current ratings, and fast response speeds to meet the miniaturization needs of modern equipment. Whether for smartphones, car infotainment systems, or precision medical instruments, selecting the right micro fuse is vital for ensuring circuit safety and stable equipment operation.

What is a Micro Fuse and Its Working Principle?

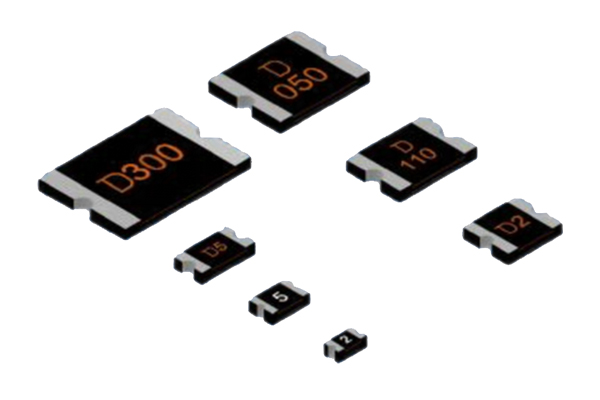

A micro fuse, also called a miniature fuse, is a current-sensitive protection device with a tiny form factor, typically used in circuits where space is limited. Unlike standard-sized fuses, micro fuses utilize thin fusible elements (such as copper or silver alloy) enclosed in a compact housing. When the current in the circuit exceeds the fuse’s rated value, the fusible element heats up and melts, quickly breaking the circuit to stop the abnormal current flow. This fast-acting protection prevents overheating of components, short circuits, and potential fires. Due to their small size (often ranging from 2.4mm×7mm to 5mm×20mm), micro fuses are ideal for dense circuit board layouts in miniaturized electronic devices.

Main Application Fields of Micro Fuses

Micro fuses are indispensable in various fields requiring compact overcurrent protection. In the consumer electronics field, they are widely used in smartphones, tablets, laptops, wearables, and home appliances (such as smart speakers and small kitchen appliances) to protect charging circuits and internal components. The automotive electronics field adopts micro fuses in car infotainment systems, dashboard electronics, LED lighting, and battery management modules, as they can withstand vibration and temperature variations. In the medical device field, micro fuses are integrated into portable medical equipment like blood glucose monitors, nebulizers, and wearable health trackers, ensuring patient safety and device reliability. Additionally, they are applied in industrial control systems (such as PLC modules and sensor circuits) and communication equipment (like routers and 5G base station components) where space efficiency is critical.

Industries Using Micro Fuses

The adoption of micro fuses spans across industries with distinct requirements. The consumer electronics industry demands ultra-compact micro fuses with low voltage ratings (32V DC or lower) to fit into slim device designs while meeting international safety standards (UL 248-14, IEC 60127). The automotive industry requires micro fuses with high temperature resistance (-40°C to 125°C) and vibration resistance, complying with automotive standards like ISO 8820 and SAE J1284. Medical device manufacturers prioritize micro fuses with medical certifications (UL 2601-1, IEC 60601-1) to ensure biocompatibility and reliability in critical healthcare equipment. The industrial automation industry uses micro fuses with higher current ratings (up to 10A) for control circuits, while the telecommunications industry needs micro fuses with fast response times to protect sensitive communication components from current surges.

Micro Fuse Product Models and Specification Parameters

Different application scenarios call for micro fuses with specific specifications. The following table lists common micro fuse models and their key parameters to assist in product selection:

| Model Number | Current Rating (A) | Voltage Rating (V AC/DC) | Dimensions (mm) | Breaking Capacity (A) | Typical Application |

|---|---|---|---|---|---|

| MF-0201 | 0.5 | 32V DC | 2.4×7.0 | 10 | Smartphones, Wearables |

| MF-0402 | 1.0 | 63V DC | 3.6×10.0 | 20 | Tablets, Laptops |

| MF-0603 | 2.0 | 125V AC/63V DC | 5.0×20.0 | 30 | Automotive Infotainment |

| MF-0805 | 3.0 | 250V AC | 6.3×30.0 | 50 | Medical Nebulizers |

| MF-1007 | 5.0 | 32V DC | 4.5×15.0 | 40 | Industrial Sensor Circuits |

Key Factors for Selecting Micro Fuses

Choosing the right micro fuse involves evaluating multiple critical factors. Firstly, current rating must match the normal operating current of the circuit—selecting a value too low may cause frequent tripping, while too high risks insufficient protection. Secondly, voltage rating should be equal to or higher than the circuit’s maximum voltage to avoid fuse breakdown. Dimensions are crucial for space-constrained applications, so ensuring the micro fuse fits the PCB footprint is essential. Additionally, consider breaking capacity (the maximum current the fuse can safely interrupt) and environmental factors (temperature, humidity, vibration) based on the application scenario. Compliance with industry certifications (UL, CE, VDE) is also necessary to meet market access and safety requirements.