Auto Fuse Introduction & Specification

Introduction

Auto Fuse is an indispensable overcurrent protection component in automotive electrical systems, playing a vital role in safeguarding circuits from damage caused by overloads and short circuits. As vehicles become increasingly electrified, modern Auto Fuse designs focus on high current capacity, excellent thermal stability, and compact sizes to adapt to the evolving needs of advanced automotive electronics. Common Auto Fuse types include blade fuses, glass tube fuses, maxi fuses, and solid-state fuses, each engineered for specific application scenarios in the automotive industry, making Auto Fuse a core element in ensuring vehicle electrical safety.

Auto Fuse Application Fields Across Industries

Auto Fuse has extensive applications across multiple vehicle sectors, with each industry leveraging its protective functions to ensure electrical system reliability. In the passenger vehicle segment, blade fuses are the most widely used Auto Fuse type, applied in lighting systems, infotainment units, and climate control circuits due to their easy replacement and consistent performance. Commercial vehicles such as trucks and buses depend on high-current Auto Fuses (up to 500A) to protect heavy-duty electrical components like starter motors, alternators, and battery management systems. The fast-growing electric vehicle (EV) and hybrid vehicle market is a key driver for specialized Auto Fuses, which require enhanced voltage tolerance (32V+) and rapid response times to safeguard battery packs, powertrain electronics, and charging systems. Additionally, the heavy-duty vehicle industry, including construction equipment and agricultural machinery, relies on durable Auto Fuses that can withstand harsh operating environments such as extreme temperatures and vibrations.

Auto Fuse Market Trends and Industry Standards

The global Auto Fuse market is experiencing steady growth, driven by the increasing electrification of vehicles and stricter safety regulations worldwide. According to Global Insights Services (2024), the Auto Fuse market is projected to grow at a CAGR of 5.7% from 2024 to 2034, reaching a market size of $5.4 billion by 2034. Leading Auto Fuse manufacturers adhere to international standards to ensure product quality and compatibility, with ISO 8820-5 being a key standard. ISO 8820-5 specifies requirements for strip fuse-links (SF 30/SF 51) with rated currents ranging from 30A to 500A and a breaking capacity of 2000A for 12V/24V automotive systems. These standards ensure that Auto Fuse products meet the safety and performance demands of various automotive applications, reinforcing their importance in the global automotive supply chain.

Common Auto Fuse Models and Specifications

Different Auto Fuse models are designed to match specific electrical requirements in vehicles. Below is a detailed table of common Auto Fuse models and their key specifications, helping to identify the right Auto Fuse for different applications:

| Model Type | Rated Current | Rated Voltage | Breaking Capacity | Application |

|---|---|---|---|---|

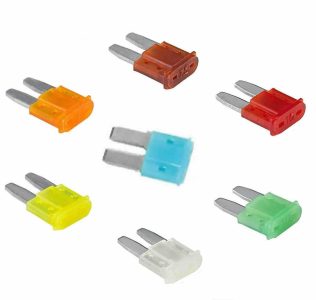

| Mini Blade Fuse | 2A-30A | 32V DC | 1000A | Passenger vehicle lighting, infotainment |

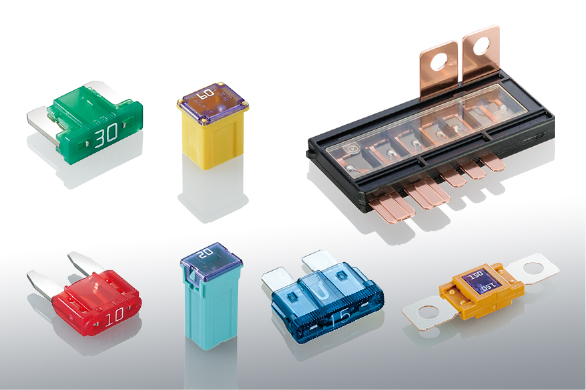

| Standard Blade Fuse | 5A-40A | 32V DC | 1500A | Climate control, power windows |

| Maxi Fuse | 20A-120A | 32V DC | 3000A | Commercial vehicle starter motors |

| Solid-State Auto Fuse | 10A-50A | 48V DC | 2000A | EV battery management systems |

Auto Fuse is a critical overcurrent protection component in automotive electrical systems, safeguarding circuits from damage caused by overloads and short circuits. With the rapid electrification of vehicles, modern Auto Fuse designs prioritize high current capacity, thermal stability, and compact sizes to meet the demands of advanced automotive electronics. Key Auto Fuse types include blade fuses, glass tube fuses, maxi fuses, and solid-state fuses, each tailored to specific application scenarios in the automotive industry.

Auto Fuse finds extensive application across multiple sectors. In the passenger vehicle segment, blade fuses are widely used in lighting, infotainment, and climate control systems due to their easy replacement and reliable performance. Commercial vehicles such as trucks and buses rely on high-current Auto Fuses (up to 500A) to protect heavy-duty electrical components like starter motors and battery management systems. The booming electric vehicle (EV) and hybrid vehicle market drives demand for specialized Auto Fuses with enhanced voltage tolerance (32V+) and rapid response times, critical for protecting battery packs and powertrain electronics. Additionally, Auto Fuses serve the heavy-duty vehicle industry, including construction equipment and agricultural machinery, where durability in harsh operating environments is essential.

The Auto Fuse market is projected to grow at a CAGR of 5.7% from 2024 to 2034, reaching $5.4 billion by 2034, fueled by increasing vehicle电子化 and stricter safety regulations (Global Insights Services, 2024). Leading manufacturers adhere to international standards like ISO 8820-5, which specifies requirements for strip fuse-links (SF 30/SF 51) with rated currents from 30A to 500A and breaking capacity of 2000A for 12V/24V systems. Below is a table of common Auto Fuse models and their specifications:

| Model Type | Rated Current | Rated Voltage | Breaking Capacity | Application |

|---|---|---|---|---|

| Mini Blade Fuse | 2A-30A | 32V DC | 1000A |