Ultra-High-Current Mega Fuse for Heavy-Duty Automotive & Industrial Protection

Introduction

Mega Fuse is an ultra-robust high-current protection component engineered for heavy-duty electrical systems, providing reliable overcurrent and short-circuit defense. With its large bolt-down design and exceptional current-handling capacity (100A-500A), it safeguards critical circuits in automotive, marine, and industrial applications like EV battery packs and large inverters. Compatible with standard Mega fuse holders, it’s essential for protecting high-power systems from catastrophic damage.

Key Features of Mega Fuse

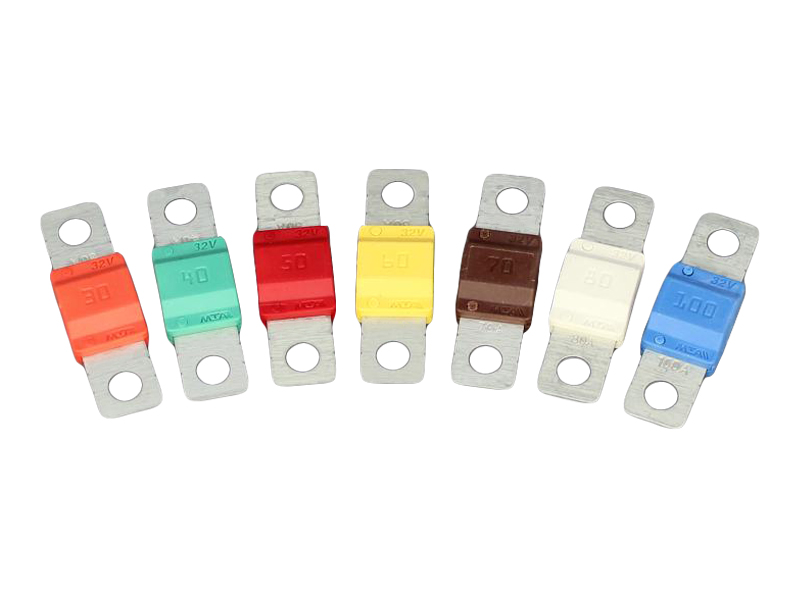

Mega Fuse stands out for its ultra-high current capacity and rugged construction, tailored for heavy-duty scenarios. It features a large ceramic or fiberglass-reinforced plastic housing with a thick silver-plated copper or zinc alloy element, ensuring superior conductivity and heat dissipation during extreme overloads. The heavy-duty bolt-down terminals (typically 3/8″ or 1/2″ studs) create a low-resistance, vibration-resistant connection, preventing arcing and terminal melting under peak loads. Mega Fuses boast an interrupting rating of up to 50,000A at 32V DC, capable of safely stopping massive fault currents in high-power systems. They are color-coded by amperage (e.g., 200A=yellow, 300A=red, 400A=blue) for rapid identification during installation and maintenance.

Application Fields of Mega Fuse

Mega Fuse is critical in electric vehicle (EV) high-voltage systems, protecting main battery packs, traction inverters, and fast-charging circuits in passenger EVs, commercial electric buses, and electric trucks. In marine applications, it safeguards large boat battery banks, marine inverters, and propulsion systems from short circuits caused by saltwater exposure. It’s also essential in industrial power distribution for forklifts, large generators, and welding equipment, where ultra-high current protection is non-negotiable. Additionally, Mega Fuses are used in renewable energy systems (large solar inverters, wind turbine converters) and RVs with high-power setups (e.g., 48V battery systems with large inverters).

Application Industries of Mega Fuse

The electric vehicle manufacturing industry integrates Mega Fuses into EV and hybrid vehicle designs, complying with strict safety standards like ISO 6469-3 and IEC 60269-6. The automotive aftermarket supplies Mega Fuses for EV conversions and heavy-duty vehicle upgrades, such as off-road trucks with high-power winches. The marine industry uses Mega Fuses in large yachts, workboats, and marine equipment, adhering to ABYC (American Boat & Yacht Council) guidelines for high-current safety. The industrial machinery sector relies on them for material handling equipment and power tools, while the renewable energy industry incorporates them into utility-scale solar and wind power installations.

Mega Fuse Model Specifications and Parameters

| Parameter Item | Specification |

|---|---|

| Product Type | Mega Fuse (Ultra-High-Current Protection Fuse) |

| Voltage Rating | DC 32V, AC 250V |

| Current Rating Range | 100A – 500A (Common Ratings: 200A, 300A, 400A, 500A) |

| Interrupting Rating | 50,000A at 32V DC |

| Body Material | Housing: Ceramic/Fiberglass-Reinforced Plastic; Element: Silver-Plated Copper/Zinc Alloy |

| Terminal Type | Bolt-Down Studs (3/8″ or 1/2″ Thread) |

| Operating Temperature Range | -40℃ to 125℃ |

| Safety Certifications | UL, CE, RoHS, IEC 60269-6 |

For professionals in heavy-duty electrical sectors, Mega Fuse is the go-to solution for ultra-high current circuit protection. Its rugged build, exceptional interrupting rating, and compatibility with standard holders make it ideal for safeguarding high-value, high-power systems. By selecting the correct amperage rating and following proper installation protocols, users ensure maximum safety and minimize downtime caused by electrical faults in demanding applications.