Easy-Integration Thermal Fuse Simplifies Upgrades to Vehicle Electrical Systems and Safety Design

News 2025-11-27

Thermal fuses are becoming a cornerstone of modern vehicle electrical protection as engineers upgrade legacy platforms to handle higher power loads. Rising adoption of electric power steering, heated comfort features, and advanced driver electronics places significant thermal stress on wiring harnesses, junction boxes, and power distribution units. An easy‑integration thermal fuse allows OEMs and tier suppliers to enhance safety margins, comply with stricter standards, and reduce redesign cycles while maintaining compact module layouts.

Drop‑In Integration for Existing Harnesses

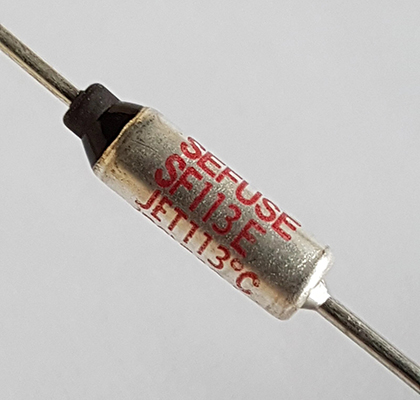

A key advantage of an easy‑integration thermal fuse is its mechanical compatibility with common vehicle connector systems and PCB footprints. Compact radial or axial packages can be inserted into existing fuse blocks, relay modules, or inline harness locations with minimal layout changes. Pre‑terminated leads and standardized pin spacing simplify automated assembly and retrofit projects in aftermarket upgrades. This drop‑in approach shortens validation time, supports platform sharing across vehicle lines, and avoids complex redesign of wiring architecture when higher current accessories are added.

Thermal Performance and Protection Characteristics

Unlike standard resettable devices, a thermal fuse provides one‑shot, predictable cutoff at a defined temperature threshold. Precise opening temperatures, tight tolerance bands, and fast response to over‑temperature events protect wire insulation, battery lines, and DC‑DC converter outputs from thermal runaway. Low internal resistance keeps power loss and heat generation minimal during normal operation, supporting higher efficiency in 12 V and 48 V electrical systems. High breaking capacity ratings ensure safe interruption of fault currents found in starter lines, PTC heaters, and high‑load comfort modules.

Automotive Application Scenarios

In passenger cars, thermal fuses are widely deployed in seat heating, window defoggers, HVAC blowers, and USB‑C fast‑charging hubs, where localized hot spots can occur. In HEV and EV platforms, they safeguard on‑board chargers, battery junction boxes, and auxiliary inverters exposed to continuous high current. Commercial vehicles and construction equipment benefit from thermal fuses in high‑duty lift systems and cabin climate units operating under harsh ambient conditions. By tailoring trip temperature and current rating, engineers can match each fuse variant to specific mission profiles and regulatory requirements.

Design Benefits for OEMs and Upgraders

The easy‑integration thermal fuse supports modular design strategies, enabling manufacturers to offer multiple equipment levels without redesigning the fundamental electrical backbone. Simplified qualification, clear datasheet parameters, and compatibility with standard crimp, solder, or press‑fit processes lower engineering effort and production cost. Serviceability also improves, as technicians can quickly identify and replace a triggered fuse during maintenance or retrofit installations. These attributes make the component attractive not only for factory build but also for authorized aftermarket upgrades seeking enhanced safety and compliance.

1、How does a thermal fuse differ from a standard blade fuse?

A thermal fuse reacts primarily to temperature rather than only current, opening the circuit when surrounding materials reach a critical temperature that could damage insulation or components.

2、Where should designers place thermal fuses in a vehicle system?

They are typically located near potential hot spots such as heaters, high‑current converters, or compact enclosures where airflow is limited and heat accumulation is likely.

3、Are easy‑integration thermal fuses suitable for EV platforms?

Yes, properly rated thermal fuses support 48 V and higher auxiliary circuits in EVs, protecting chargers, junction boxes, and cabin comfort loads under demanding thermal conditions.