Space-Saving Thermal Fuse Design Boosts Protection In Modern Automotive Electrical Systems

News 2025-11-27

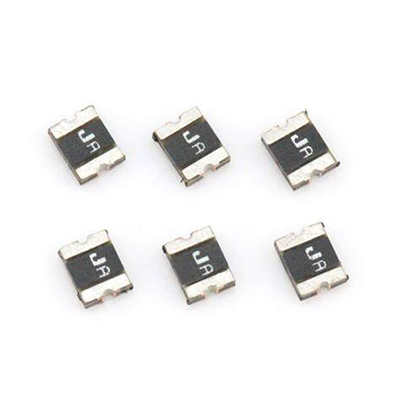

Compact-design thermal fuses are reshaping protection strategies in modern vehicles by enabling higher circuit density without sacrificing safety. As automotive platforms integrate advanced driver assistance, infotainment, and electrified powertrains, engineers must handle rising power levels inside ever-smaller modules. The compact thermal fuse addresses this challenge by combining miniature size, precise temperature cut-off, and high interrupt capability. It allows designers to protect sensitive circuits housed in tight spaces such as control units, battery management systems, and in-cabin electronics.

Key Applications In Automotive Electrical Architectures

Compact thermal fuses are widely deployed in DC/DC converters, onboard chargers, seat heating modules, HVAC blowers, LED lighting systems, and infotainment equipment. In battery electric and hybrid vehicles, they safeguard high-density lithium-ion packs, cell-balancing circuits, and junction boxes, helping to prevent overheating from abnormal current or component failure. The reduced package height supports placement directly on densely populated PCBs inside engine bay ECUs, where space is limited and vibration levels are high. Their presence supports compliance with automotive safety standards while allowing tighter packaging of wiring harnesses and distribution boards.

Performance Advantages Of Compact Thermal Fuses

The compact design lowers footprint and board area while maintaining consistent opening temperature and stable resistance. Fast thermal response rapidly disconnects the circuit once the threshold temperature is exceeded, limiting thermal runaway and collateral damage. Low internal resistance helps minimize power loss, which is crucial in high-efficiency power stages of traction inverters and power distribution modules. Many versions offer high voltage and current ratings suitable for 12 V, 24 V, and emerging 48 V systems, supporting both legacy architectures and next-generation platforms.

Mechanical Robustness And Integration Benefits

Automotive-grade thermal fuses are engineered to withstand temperature cycling, humidity, and shock typical of under-hood and chassis locations. Reinforced lead structure and robust encapsulation improve solder joint reliability under vibration. The small form factor simplifies routing on multilayer PCBs and facilitates integration into compact connector housings and fuse boxes. Designers can optimize thermal coupling by placing the fuse close to heat-generating components, achieving accurate sensing of local hot spots. This level of integration reduces wiring complexity and assembly steps, supporting scalable, modular electrical architectures.

Design Considerations And Selection Criteria

When selecting a compact thermal fuse for automotive use, engineers evaluate opening temperature, holding temperature, rated current, and interrupt capacity. Proper margin must be maintained between normal operating temperature and the fuse’s cut-off threshold to avoid nuisance tripping during peak load or high ambient conditions. Compatibility with reflow soldering profiles, compliance with AEC-Q standards, and traceability requirements are also key. Coordinating thermal fuses with electronic protection devices such as MOSFET-based switches and resettable polymer devices produces layered protection, increasing system robustness in advanced electrical and electronic (E/E) architectures.

FAQ: Compact Thermal Fuses In Car Electrical Systems

1. How does a compact thermal fuse improve space utilization in ECUs?

The miniature package allows the fuse to be placed directly on crowded PCBs, freeing area in fuse boxes and enabling smaller, lighter ECU housings.

2. Why choose a thermal fuse instead of only electronic protection?

A thermal fuse provides a permanent, temperature-driven cutoff that works independently of firmware or control logic, adding a fail-safe layer when electronics malfunction.

3. Are compact thermal fuses suitable for high-voltage EV battery circuits?

Many automotive-rated versions support elevated voltage and current levels, making them appropriate for segments of EV battery and power distribution systems when selected according to system specifications.