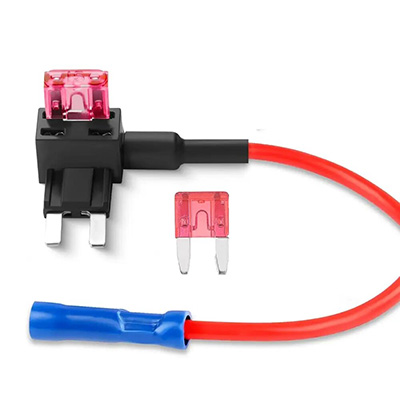

Inline Fuse Holder: Flexible Circuit Protection for Diverse Wiring Setups

Introduction

An inline fuse holder is a wire-mounted overcurrent protection component designed to house fuses in the middle of electrical circuits, safeguarding devices from overcurrent and short circuits. Widely used in automotive, marine, industrial, and DIY electronics, inline fuse holders offer flexible installation, compatibility with various fuse types, and durable performance. Whether for car audio systems, boat wiring, or outdoor lighting, selecting the right inline fuse holder ensures circuit safety and easy fuse replacement.

What is an Inline Fuse Holder and Its Working Principle?

An inline fuse holder is a cylindrical or rectangular device that connects directly to electrical wires, holding a fuse in series with the circuit. Unlike panel-mounted fuse holders that attach to fuse boxes, inline versions are installed along the wire run, making them ideal for circuits where a fuse box is inaccessible. When current flows through the circuit, it passes through the fuse inside the holder. If an overcurrent event occurs, the fuse melts, breaking the circuit and protecting connected devices. The holder’s design allows for quick fuse replacement—most models feature a twist-off or snap-open cap, eliminating the need for tools. Additionally, many inline fuse holders include waterproof or dustproof housings to withstand harsh environments.

Core Application Fields of Inline Fuse Holders

Inline fuse holders are versatile components used in fields requiring on-wire protection. In the automotive field, they are essential for aftermarket electronics like car audio amplifiers, subwoofers, LED light bars, and auxiliary power outlets, as they protect wiring from current surges. The marine field utilizes waterproof inline fuse holders for boat wiring, including navigation lights, fish finders, and bilge pumps, ensuring protection against water damage. In industrial settings, they are used in machinery wiring, conveyor systems, and power tools, where flexible circuit protection is needed. Additionally, inline fuse holders are popular in DIY electronics for projects like outdoor lighting, solar panel setups, and hobbyist circuits, as well as in RVs and campers for powering accessories like refrigerators and camping lights.

Industries Utilizing Inline Fuse Holders

The demand for inline fuse holders spans industries focused on flexible and reliable circuit protection. The automotive aftermarket industry is a major user, with inline fuse holders required for installing high-power accessories—complying with standards like SAE J1128. Marine electronics manufacturers recommend waterproof inline fuse holders that meet ABYC (American Boat and Yacht Council) standards for saltwater and damp environments. The industrial manufacturing sector uses heavy-duty inline fuse holders for machinery, ensuring compliance with IEC 60947-1 for industrial safety. DIY and hobby electronics industry offers compact, affordable inline fuse holders for home projects, with UL certification for household use. Furthermore, the renewable energy industry uses inline fuse holders in solar panel systems to protect wiring from current fluctuations, adhering to NEC (National Electrical Code) guidelines.

Inline Fuse Holder Product Models and Specification Parameters

Different circuit requirements call for inline fuse holders with specific specifications. Below is a table of common models and their key parameters to aid selection:

| Model Number | Fuse Type Compatibility | Max Current Rating (A) | Wire Gauge Range | Protection Rating | Typical Application |

|---|---|---|---|---|---|

| IFH-BLADE-M | Mini Blade Fuse | 20 | 14-18 AWG | IP67 Waterproof | Car LED Light Bars, Auxiliary Outlets |

| IFH-BLADE-STD | Standard Blade Fuse | 30 | 12-16 AWG | IP44 Dustproof | Car Audio Amplifiers, RV Refrigerators |

| IFH-GLASS-5×20 | 5x20mm Glass Fuse | 10 | 16-20 AWG | IP54 Splashproof | DIY Electronics, Indoor Lighting |

| IFH-MAXI-MARINE | Maxi Blade Fuse | 50 | 8-12 AWG | IP68 Waterproof | Marine Bilge Pumps, Boat Navigation Systems |

| IFH-CART-AGC | AGC Cartridge Fuse | 15 | 14-18 AWG | IP40 Dustproof | Solar Panel Wiring, Industrial Sensors |

Key Considerations When Choosing Inline Fuse Holders

Selecting the appropriate inline fuse holder involves evaluating critical factors. Fuse type compatibility is essential—match the holder to the fuse type used in your circuit (e.g., mini blade, glass). Max current rating must exceed the circuit’s operating current to avoid premature tripping; for example, a 25A circuit needs a holder rated for at least 25A. Wire gauge range should fit the thickness of your wiring to ensure a secure connection. Protection rating (IP code) depends on the environment: IP67/IP68 for wet areas (marine, outdoor), IP44 for dusty indoor spaces. Additionally, check for installation ease (crimp-on, solder-on, or screw-terminal) and certifications (UL, CE, SAE) to meet safety standards. Always mount the holder in a accessible location for easy fuse replacement.