Heavy-Duty Midi Fuse for High-Current Automotive & Marine Protection

Introduction

Midi Fuse is a robust high-current protection component designed for medium-to-heavy-duty electrical systems, delivering reliable overcurrent and short-circuit defense. With its compact yet durable design and bolt-down terminals, it safeguards circuits in automotive, marine, and industrial applications handling 30A-200A currents. Easy to install and compatible with standard Midi fuse holders, it’s essential for protecting high-power components like inverters and battery banks.

Key Features of Midi Fuse

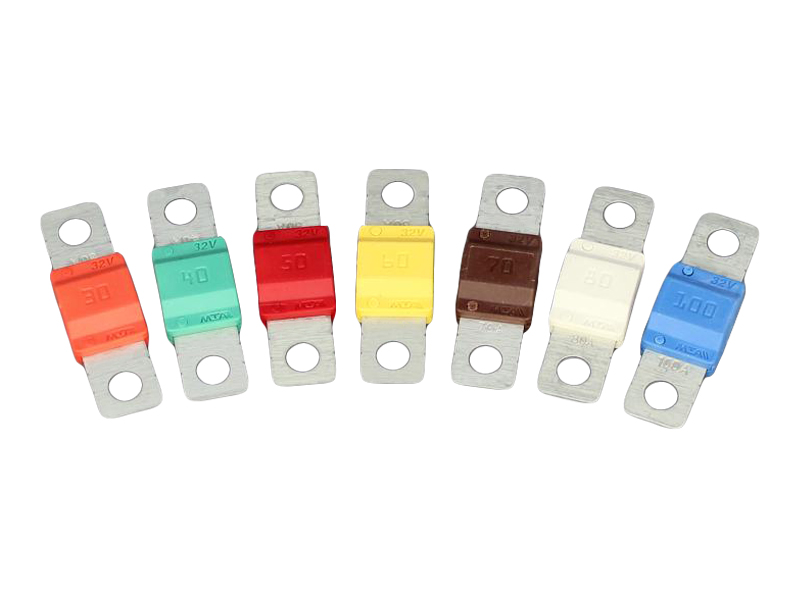

Midi Fuse stands out for its balance of high-current capacity and space-saving design. It features a cylindrical or rectangular ceramic body with a zinc alloy or silver-plated copper element, ensuring excellent conductivity and heat resistance during overloads. The integrated bolt-down terminals (typically 6mm or 8mm studs) provide a secure, low-resistance connection, preventing arcing and overheating under heavy loads. Midi Fuses have an interrupting rating of up to 20,000A at 32V DC, effectively stopping fault currents in high-power systems. They are also color-coded by amperage (e.g., 50A=yellow, 100A=red, 150A=blue) for quick visual identification during installation and maintenance.

Application Fields of Midi Fuse

Midi Fuse is widely used in automotive high-power systems, including electric vehicles (EVs), hybrid vehicles, and heavy-duty trucks, protecting circuits for battery chargers, DC/DC converters, and auxiliary power units. In marine applications, it safeguards boat battery banks, trolling motors, and onboard inverters from short circuits caused by saltwater exposure or wiring faults. It’s also essential in RVs and campers for protecting 12V/24V power distribution systems connected to solar panels or generators. Additionally, Midi Fuses find use in industrial equipment like forklifts and small generators, where medium-to-high current protection is required.

Application Industries of Midi Fuse

The automotive manufacturing industry integrates Midi Fuses into EV and hybrid vehicle designs, complying with safety standards such as IEC 60269-3. The automotive aftermarket supplies Midi Fuses for vehicle upgrades, including off-road modifications and high-performance audio systems. The marine industry uses Midi Fuses in boat production and maintenance, adhering to ABYC (American Boat & Yacht Council) electrical safety guidelines. The RV and recreational vehicle industry incorporates them into power system kits for campers and motorhomes. Additionally, the industrial equipment sector relies on Midi Fuses for protecting medium-current circuits in material handling and portable power devices.

Midi Fuse Model Specifications and Parameters

| Parameter Item | Specification |

|---|---|

| Product Type | Midi Fuse (High-Current Protection Fuse) |

| Voltage Rating | DC 32V, AC 250V |

| Current Rating Range | 30A – 200A (Common Ratings: 50A, 70A, 100A, 150A, 200A) |

| Interrupting Rating | 20,000A at 32V DC |

| Body Material | Housing: Ceramic; Element: Zinc Alloy/Silver-Plated Copper |

| Terminal Type | Bolt-Down Studs (6mm/8mm Thread) |

| Operating Temperature Range | -40℃ to 125℃ |

| Safety Certifications | UL, CE, RoHS, IEC 60269-3 |

For professionals in automotive, marine, or industrial fields, Midi Fuse is a reliable solution for medium-to-high current circuit protection. Its durable ceramic construction, high interrupting rating, and easy installation make it ideal for safeguarding valuable high-power components. By selecting the appropriate amperage rating and pairing it with compatible Midi fuse holders, users ensure the safety and longevity of their electrical systems even under demanding operating conditions.