High-Durability Engine Wire Harness for Automotive & Industrial Applications

Introduction

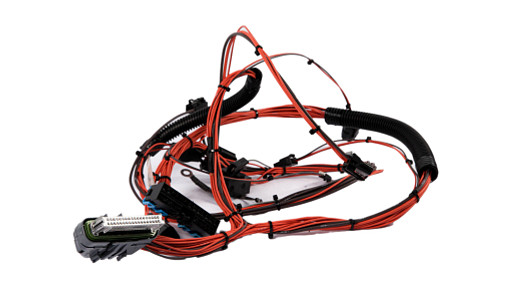

A high-durability Engine Wire Harness is a critical component that organizes and transmits electrical signals between engine parts and vehicle/industrial systems. It ensures reliable power distribution and communication, withstanding high temperatures, vibration, and chemical exposure. Widely used in automotive engines, industrial machinery, and heavy-duty equipment, our engine wire harnesses are engineered for performance and longevity.

Key Features of Engine Wire Harness

Our Engine Wire Harness is built with premium materials to endure harsh operating conditions. It uses high-temperature resistant wires (up to 200°C) and flame-retardant insulation (UL94 V-0 rating) to resist heat from engine components. The harness features corrosion-resistant terminals (tinned copper or brass) and robust shielding (braided or foil) to prevent electromagnetic interference (EMI). It’s designed with precise wire routing and secure bundling to minimize vibration-induced wear, while waterproof connectors (IP67/IP68) are available for wet environments. Customizable wire gauges (10-24 AWG) and connector types (AMP, Delphi, Yazaki) ensure compatibility with diverse engine systems.

Application Fields of Engine Wire Harness

This Engine Wire Harness is essential in various high-demand fields. In automotive engines, it connects ECUs, sensors, fuel injectors, and ignition systems, ensuring smooth engine performance and emissions control. In industrial machinery (e.g., generators, pumps), it transmits signals between engine controls and monitoring devices. For heavy-duty vehicles (trucks, construction equipment), it withstands extreme vibration and temperature fluctuations to power engine accessories. In marine engines, waterproof versions link engine components to navigation and propulsion systems, resisting saltwater corrosion.

Application Industries of Engine Wire Harness

Multiple industries rely on our Engine Wire Harness for critical electrical connectivity. The automotive manufacturing industry uses it in passenger cars, electric vehicles, and commercial trucks as original equipment. The industrial equipment industry incorporates it into generators, compressors, and agricultural machinery. The heavy-duty and construction industry depends on it for excavators, bulldozers, and mining vehicles. The marine industry utilizes waterproof versions in boat and yacht engines. Additionally, the power generation industry applies it in diesel and gas engine-powered generators.

Product Model Specifications and Parameters

| Model Number | Wire Gauge | Max Temp Resistance | Waterproof Rating | Connector Type | Shielding | Application |

|---|---|---|---|---|---|---|

| EWH-A100 | 12-20 AWG | 150°C | IP65 | AMP | Foil Shield | Automotive Engines |

| EWH-I200 | 10-18 AWG | 200°C | IP67 | Delphi | Braided Shield | Industrial Machinery |

| EWH-H300 | 8-16 AWG | 180°C | IP66 | Yazaki | Double Shield | Heavy-Duty Vehicles |

| EWH-M400 | 12-22 AWG | 160°C | IP68 | AMP | Foil + Braided Shield | Marine Engines |

Why Choose Our Engine Wire Harness

Our Engine Wire Harness stands out for reliability and customization. Each harness undergoes strict testing, including high-temperature endurance, vibration resistance, and electrical performance checks, complying with ISO/TS 16949 and IEC standards. We offer custom designs tailored to specific engine models and application requirements, from wire length to connector configuration. The use of premium materials ensures long service life even in harsh environments. With competitive pricing, efficient production lead times, and expert technical support, we provide a trusted electrical connectivity solution for your engine and machinery needs.