High-Performance Powertrain Wire Harness for Vehicle Propulsion Systems

Introduction

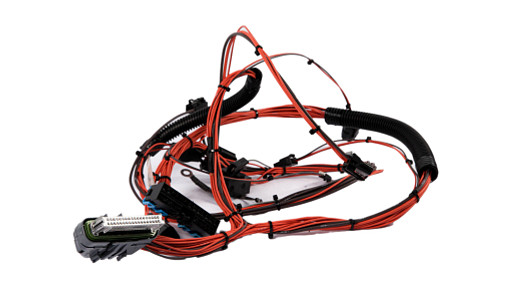

A reliable Body Wire Harness is a key electrical component that connects and organizes wiring for vehicle interior and exterior systems. It transmits power and signals to components like lights, doors, seats, and infotainment, ensuring seamless operation. Widely used in passenger cars, commercial vehicles, and electric vehicles, our body wire harnesses are engineered for durability and space efficiency.A high-performance Powertrain Wire Harness is a critical electrical backbone for vehicle propulsion systems, transmitting power and signals between engines, transmissions, and control units. It endures extreme torque, temperature, and vibration, ensuring seamless coordination of powertrain components. Widely used in gasoline/diesel vehicles, electric vehicles, and hybrid cars, our powertrain wire harnesses are engineered for reliability and efficiency.

Key Features of PowertraBody Wire Harness

Our Body Wire Harness is designed with vehicle interior/exterior demands in mind. It uses flexible, abrasion-resistant wires (16-24 AWG) and halogen-free insulation (UL94 V-0) to meet automotive safety standards. The harness features compact bundling and precise routing to fit tight spaces in door panels, dashboards, and seat structures. Corrosion-resistant terminals (tin-plated copper) ensure stable connections, while optional shielding (foil or braided) reduces interference for infotainment and sensor signals. It supports waterproof connectors (IP65/IP67) for exterior components like tail lights and door locks, with customizable lengths and connector types (TE, Molex, Yazaki) for diverse vehicle models.Our Powertrain Wire Harness is built to withstand the harshest propulsion system conditions. It uses high-temperature resistant conductors (up to 220°C) and flame-retardant, oil-resistant insulation (XLPE or PTFE) to resist engine oil, fuel, and coolant exposure. The harness features robust strain relief and vibration-dampening bundling to handle powertrain torque and movement. Corrosion-resistant terminals (gold-plated or nickel-plated copper) ensure low-resistance power transmission, while multi-layer shielding (braided + foil) blocks electromagnetic interference (EMI) from high-voltage components. Customizable wire gauges (6-20 AWG) and high-voltage compatibility (up to 800V) suit gasoline, hybrid, and electric vehicle powertrains.

Application Fields of PowertraBody Wire Harness

This Body Wire Harness is essential for vehicle body electrical systems. In vehicle interiors, it connects dashboards, infotainment systems, power seats, and climate controls, ensuring smooth user experience. In exterior components, it links headlights, tail lights, turn signals, and door locks, supporting safety functions. For electric vehicles (EVs), it integrates with battery management systems and charging ports to transmit power and status signals. In commercial vehicles (vans, buses), it powers passenger area lights, door controls, and onboard communication devices.This Powertrain Wire Harness is essential for vehicle propulsion coordination. In gasoline/diesel vehicles, it connects engines, transmissions, ECUs, and sensors, ensuring precise fuel injection and gear shifting. In hybrid electric vehicles (HEVs), it links internal combustion engines with electric motors and battery management systems. For battery electric vehicles (BEVs), high-voltage versions transmit power between motors, inverters, and batteries, with safety features for high-current operation. In heavy-duty trucks, it endures extreme loads to coordinate large diesel engines and transmission systems.

Application Industries of PowertraBody Wire Harness

Multiple industries rely on our Body Wire Harness for vehicle electrical connectivity. The automotive manufacturing industry uses it in passenger cars, SUVs, and EVs as original equipment. The commercial vehicle industry incorporates it into buses, trucks, and delivery vans. The electric vehicle industry depends on it for integrating body systems with EV powertrains. The automotive aftermarket industry offers it for vehicle repairs and customization. Additionally, the specialty vehicle industry utilizes it in ambulances, RVs, and modified cars for tailored electrical setups.Multiple industries rely on our Powertrain Wire Harness for propulsion system reliability. The automotive manufacturing industry uses it in passenger cars, SUVs, and light trucks as original equipment. The electric vehicle industry depends on high-voltage versions for BEVs and PHEVs. The commercial trucking industry incorporates it into heavy-duty diesel and hybrid trucks. The off-highway vehicle industry utilizes it in construction equipment and agricultural machinery. Additionally, the marine propulsion industry applies it in boat and ship powertrains for engine-transmission coordination.

Product Model Specifications and Parameters

| Model Number | Wire Gauge | Max Temp Resistance | Voltage Rating | Connector Type | Shielding | Application |

|---|---|---|---|---|---|---|

| PWH-G100 | 10-20 AWG | 180°C | 12V/24V | Delphi | Braided Shield | Gasoline/Diesel Vehicles |

| PWH-H200 | 8-18 AWG | 200°C | 48V | TE | Foil + Braided Shield | Hybrid Electric Vehicles |

| PWH-E300 | 6-16 AWG | 220°C | Up to 800V | Yazaki | Multi-Layer Shield | Battery Electric Vehicles |

| PWH-T400 | 8-14 AWG | 190°C | 24V/48V | Amphenol | Double Braided Shield | Heavy-Duty Trucks |

| Model Number | Wire Gauge | Insulation Type | Waterproof Rating | Connector Type | Shielding | Application |

|---|---|---|---|---|---|---|

| BWH-C100 | 16-22 AWG | Halogen-Free PVC | IP65 | TE | Foil Shield | Passenger Cars |

| BWH-E200 | 18-24 AWG | XLPE | IP67 | Molex | Braided Shield | Electric Vehicles |

| BWH-V300 | 16-20 AWG | PVC | IP65 | Yazaki | No Shield | Commercial Vans |

| BWH-S400 | 18-22 AWG | Halogen-Free XLPE | IP67 | TE | Foil + Braided Shield | Specialty Vehicles |

Why Choose Our PowertraBody Wire Harness

Our Body Wire Harness excels in reliability and adaptability for vehicle applications. Each harness undergoes strict testing, including abrasion resistance, electrical continuity, and environmental durability checks, complying with ISO 10487 and IEC standards. We offer custom designs to match specific vehicle makes and models, optimizing wire routing for space-constrained areas. The use of high-quality insulation and terminals ensures long service life and reduced maintenance. With competitive pricing, timely delivery, and dedicated technical support, we provide a trusted electrical connectivity solution for your vehicle body systems.Our Powertrain Wire Harness is a trusted choice for vehicle propulsion systems. Each harness undergoes rigorous testing, including high-temperature endurance, vibration resistance, high-voltage insulation checks, and EMI shielding verification, complying with ISO/TS 16949 and LV124 standards. We offer custom designs tailored to specific powertrain architectures, optimizing wire routing for space and durability. The use of premium, industry-approved materials ensures long service life and reduced downtime. With competitive pricing, flexible production capacities, and expert technical support, we provide a reliable electrical backbone for your vehicle powertrain needs.